Like any rotary airlock valve, its function is to allow the flow of the product, without letting the air escape. This model is designed to also not allow the shearing or cutting of the product with the valve blades.

This valve can be used not only a sealing in the pneumatic transport’s discharge or under dust collectors, but also as a dosing media for bins. Due to its precise construction, the HSG valves ensure absolute tightness and reliance.

This valve is absolutely adequate for Its use in negative and effective pressure. It can be placed under dust collectors, air separators or bins.

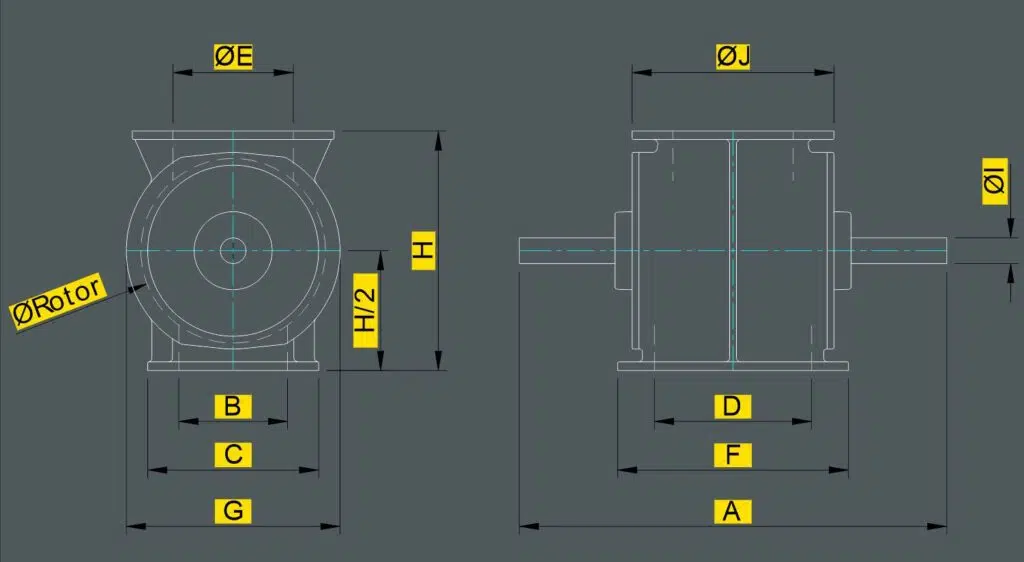

Construction details of HSG rotary lock valve

- The body and rotor are normally made up of cast iron and the shaft of carbon steel, mounted on bearings.

- However, it can be also produced in stainless steel or other materials.

- A perfect and lasting sealing is ensured due to Its exact machining.

- Special execution with chromed interior and hardened rotor for abrasive products.

This type of rotary valve is one of the 4 types of valves we have for pneumatic conveying systems. Because it does not allow shearing or cutting of the product with the valve blades, it is especially used in the dosing of granulated products such as those used as raw materials in the plastic industry. For example, polycarbonate, polyvinyl chloride or PVC, polystyrene or PET, polyethylene, polypropylene, etc.

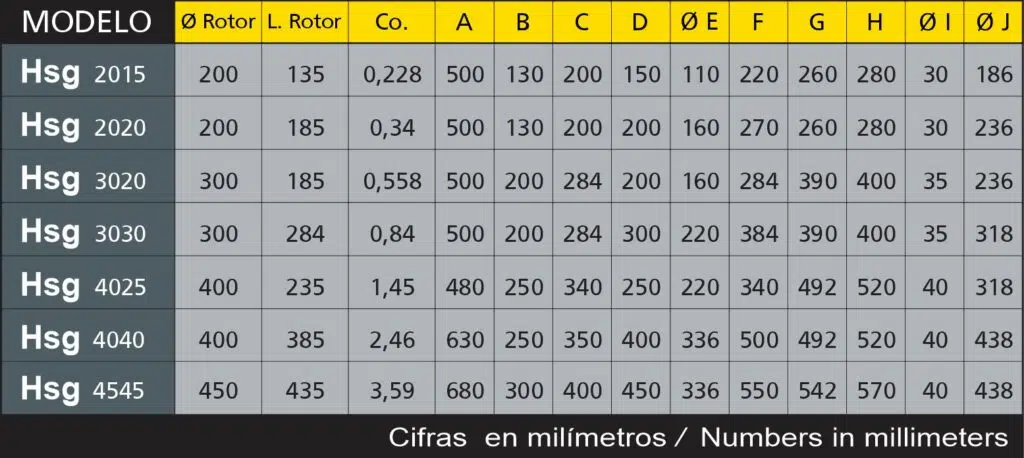

Technical information

Calculations

Capacity (Ton/h) = Co x ρ x n x α / 100

Where:

Co (m3/h x r.p.m) = Capacity at 100% fill rate for 1 r.p.m. See table.

ρ (Ton/m3) = Specific weight

n (r.p.m) = Revolutions per minute

α (%) = Valve filling percentage

More information in the following links