For industries that utilize BIG-BAGS, we offer machinery for their movement, loading, and unloading. Additionally, we provide the necessary pneumatic conveying systems and handling equipment for inserting their contents into the production line.

Due to the significant weight of the big bags, it is crucial to consider all necessary safety requirements when loading, moving, and unloading these bags within the plant.

We also prioritize ensuring that the operation is simple, avoids product waste, and prevents dust suspension in the environment.

Available equipment for loading and unloading Big Bags:

1- DBB big-bag Unloader

If you need equipment to unload large bags or sacks quickly and efficiently, we have the product you need: the DBB Big Bag Unloader.

Its proven design makes unloading maxi bags a simple and safe operation, ensuring the absence of dust in the environment and preventing the waste of raw materials.

Components of the Big Bag unloading system

- Adjustable modular height structure.

- Base with a conical hopper with a capacity of 1.2 m3 with or without vibration.

- Breathing pipe with filter sleeve.

- Bottom door to open and discharge the maxi bags without the possibility of accidents.

Optional features for Big Bag unloaders

- Optional discharge vibration. Recommended for products with difficult flow.

- To facilitate the emptying of big bags, fluidizers can be added as well.

- Another optional element that facilitates emptying is the pneumatic massager or pulsating shaker. This pneumatic element forcefully strikes the lower side of the big bag, breaking up any compaction that may occur.

- Automatic discharge cutting system. Consists of conical blades that cut the bottom of the big bag when it is resting. This makes manual opening unnecessary.

- Can be constructed in different materials, such as iron or stainless steel.

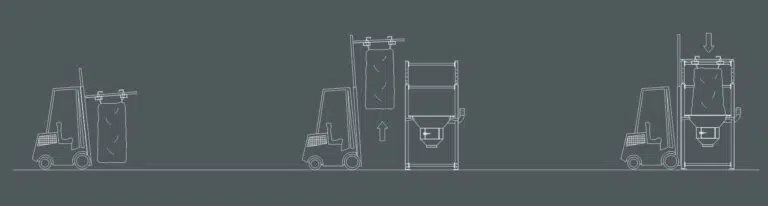

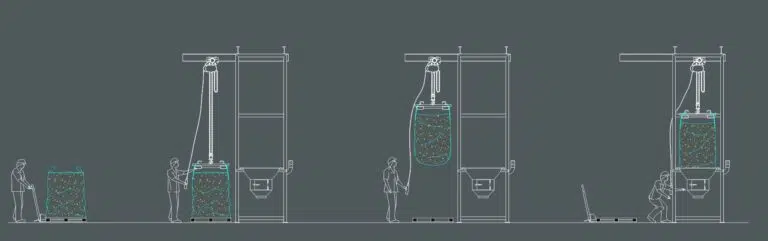

Operation mode of the DBB Big Bag unloader

- The operator hangs the big bag, placing its ears on the hooks provided by the “hanger”, which must be previously placed on the forklift’s tines. The use of this mode of transportation is important to ensure safety.

- The forklift lifts the big bag and approaches, entering it into the structure of the DBB Big Bag unloader.

- The forklift gently lowers the big bag until the “hanger” rests on the adjustable height structure and then removes it, leaving the hanger hanging. At this point, the big bag is ready for the operator to open and start unloading.

- Once the unloading is complete, the forklift retrieves the hanger and lowers it to remove the empty big bag and hang a full one.

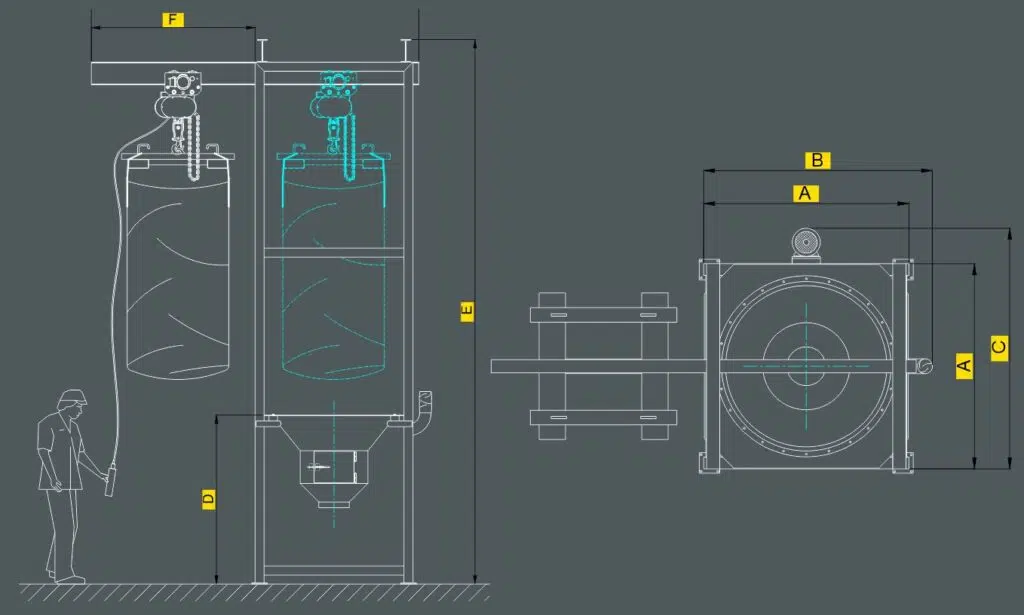

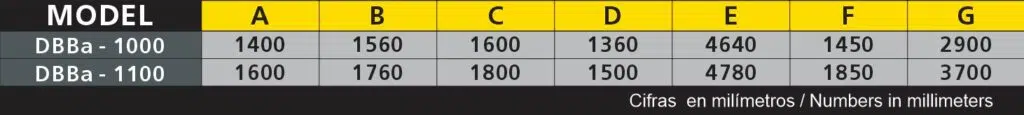

2- DBBa Big Bag unloader with rigging

The DBBa unloader with integrated rigging allows for the avoidance of using a forklift for the big bag unloading operation. In all other details, it is a machine very similar to the DBB Big Bag unloader.

To determine the most appropriate rigging, the following should be analyzed:

- Weight and height of the largest big bag to be used.

- Whether manual or electric lifting is desired.

- Whether manual or electric translation is desired.

Operation mode of the DBBa Big Bag unloader

- The operator moves the big bag with a cart and places it in the lifting area of the rigging.

- Then, they place the ears on the hooks provided by the “hanger”, which must be previously hung.

- Manually or electrically, the operator positions the big bag for opening and unloading.

- Once unloading is complete, the rigging is ready to be positioned to remove the empty big bag and hang the next full one.

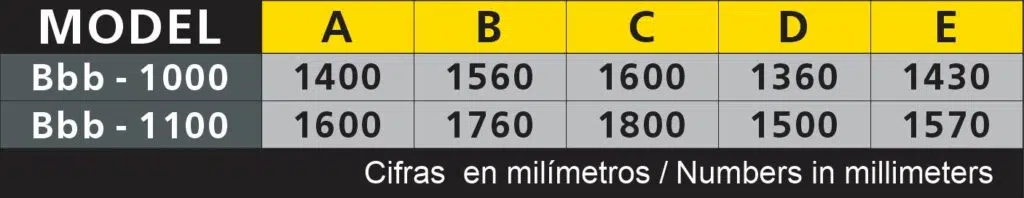

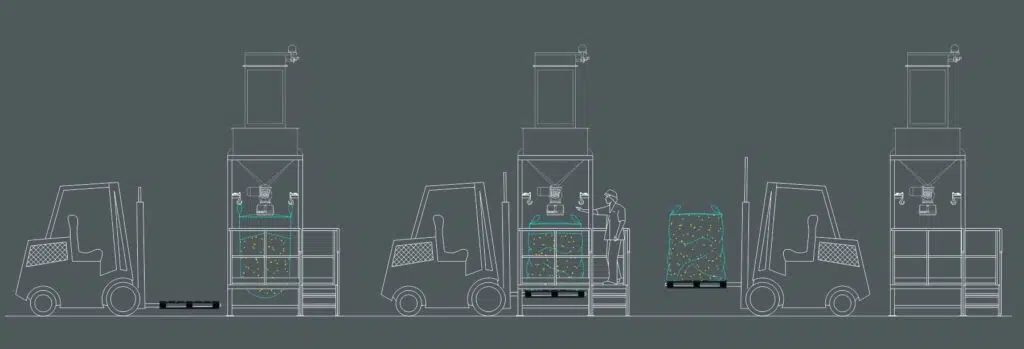

3- CBB Big Bag Loaders

Our CBB big bag loaders have been designed for the proper and safe filling of BIG-BAGS, avoiding accidents, product waste, and dust in the environment.

We mainly manufacture 2 types of loaders:

– The CBBG loader, in which filling is controlled by the scale from which the maxi bag hangs.

-The CBBV loader, in whih filling is by volume and where the stop order is given by a level sensor.

Design details and components of the Big Bag or Maxi Bag loader filler

- It features a modular height-adjustable structure suitable for the big bag to be filled.

- It is surrounded by an access structure to the elements that need to be handled by the operator; such as placing the feeding sleeve and hanging the ears or handles of the maxi bag. In cases where the bag is of low height, this structure is not required.

- It is possible to attach suction systems.

- It can be supplied in both iron and stainless steel.

Operation mode of the CBB Big Bag loader

- The operator hangs the big bag, placing its ears on the hooks provided by the loader, also securing the feeding sleeve to it.

- Filling order is given.

- Once filled, the forklift with a pallet on its tines approaches and slightly lifts the big bag, allowing the operator to unhitch it. The feeding sleeve is also tied off.

- This way, the forklift can carry away the big bag.

- The operator hangs a new empty big bag, and the cycle restarts. The flow of material to be filled does not stop, as there is an upper reservoir that stores the product while the bags are changed.

Common raw materials handled in Big Bags:

- Wheat

- Maize

- Oats

- Coffee

- Cocoa

- Rye

- Beat

- Rice

- Girassol

- Chickpeas

- Soybeans

- Peanuts

- Peanuts

- Spices

- Balanced feed

- Pellets or feeds

- Crystalline sugar

- Impalpable sugar

- Cocoa

- Coffee

- Coriander

- Curcuma

- Gelatin

- Bone meal

- Fish flour

- Milk powder

- Dried beans

- Bread crumbs

- Batter

- Aluminum powder

- Atrazine

- Bentonite

- Borax powder

- Lime

- Caolin

- Activated carbon

- Calcium carbonate

- Cement

- Shell

- Quartz

- Titanium Dioxide

- Dolomite

- Fertilizers

- Monoammonium Phosphate

- Diammonium Phosphate

- Tricalcium Phosphate

- Mica

- Refractory Materials

- Sodium naphthalenesulfonate

- Pigments

- Soaps

- Salt

- Precipitated silica

- Caustic soda

- Magnesium sulfate

- Zinc sulfate

- Tanine

- Diatomaceous Earth

- Dyes

- Gypsum

- Lithium

- Afrecho and afrechillo

- Wheat semolina and semolina

- Semolina

- Rebasillo

- Zootechnical flour

- Maize semolina

- Semolina

- Polenta

- Wheat flour, corn flour, soy flour, etc.

- Germ

- Starch

- Hull

- Polycarbonate

- Vinyl polyvinyl chloride or PVC

- Polystyrene or PET

- Polyethylene

- Polypropylene

- Expanded polystyrene (Styrofoam)

- Sawdust

- Wood

- Cork

- Soap poder

- Pigments