Classification of Processes to Which Cereals Can Be Subjected to Improve Their Nutritional Characteristics

The processes to which cereals are subjected to improve their nutritional characteristics can be classified as cold and hot. This is a primary classification but useful for understanding the importance of how they are exposed for biological use.

- Among the cold processes, the most used are milling, cracking, and crushing.

- Among the hot processes are micronizing, flaking, pelleting, and extrusion and expansion.

Hot processes can be further divided into wet and dry methods. In wet processes, water and temperature are used in the form of steam, and in dry processes, only temperature is used.

Achieving Good Gelatinization; The Goal for Increasing Digestibility

The most commonly used methods to improve the nutritional characteristics of cereals are thermal or hydrothermal, combined with a mechanical treatment. The main goal is to disrupt the crystalline structure of starch to achieve gelatinization.

These procedures alter starches that have hydroxyl groups, which are poorly soluble in water. The alteration of these groups by hydrothermal processes increases water retention capacity and facilitates the swelling and gelatinization of starch grains. Pre-gelatinized starches, cooked by extrusion or on rollers and then dried, swell directly in cold water, which they retain well. The temperature at which these phenomena occur is called the gelatinization temperature and is associated with the breaking of the secondary hydrogen bonds that hold the polymer chains together. The gelatinization temperature for barley is in the range of 59-64°C, for wheat 65-67°C, and for sorghum between 67 and 77°C.

Understanding the pre-gelatinization process is important for comprehending the practical significance of easier starch digestion by animals.

In corn and sorghum grains, the notable increase in ruminal and post-ruminal digestibility is achieved through steam treatment and flake formation. One of the objectives of supplementing with this type of grain is to provide energy to the rumen, especially in pastures with high protein content and degradability (alfalfa, winter greens, fresh quality forage). The choice of grain type to use is of utmost importance to harmonize (balance) energy and protein availability at the rumen level.

It is important to note that starch gelatinization by cooking makes it more digestible than by amylolytic enzymes.

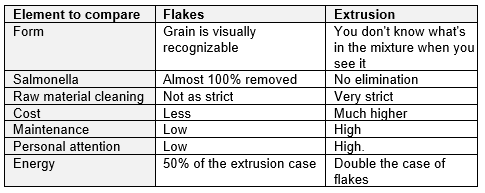

Comparison between extrusion and flaking:

Fundamental is the advantage that, in flaking manufacture, the grain is recognizable. This gives greater security to the buyer as the food components are visible. Microorganisms such as salmonella are totally eliminated in the steam cooking tower as there is prolonged contact with the heat (15 to 60 minutes).

Products to Obtain with the Flake Production Line:

It is possible to produce single-grain flakes or make mixtures of them before crushing. In cases where vitamins, etc., are to be added, they can be mixed with pellets containing these micro-components afterward.

Raw material: Mixture of grains.

End product: Crushed grains.

Final Product: With pellets.

Raw material: Mixture of grains.

End product: Crushed grains.

Final Product: With pellets.

Description of the Flake Production Process:

As we have seen, to achieve high digestibility of the feed, the available technologies are extrusion and flake production. Pelleting with a press is not comparable due to obtaining lower gelatinization. Flake production is a thermo-mechanical process of “cooking-rolling” to which cereals are subjected. Cooking is done with low-pressure steam while rolling basically consists of crushing the grain into thin sheets. This way, the starch in the grains is transformed into less complex substances such as dextrins and sugars (chemical effect of heat-pressure), and the starch grains lose their crystalline structure, resulting in gelatinization (physical effect). The product obtained after drying is called “cereal flakes,” whose advantages are:

- Eliminate bacteria and potentially the development of toxins that can appear under prolonged storage conditions.

- Inactivate anti-nutritional factors.

- Modify the physical appearance of the food.

- Increase bulkiness.

- Enhance the imbibition degree of particles.

- Increase starch digestibility by transforming it into dextrins.

The process is articulated in three phases:

Phase 1: Hydrothermal Treatment.

It consists of uniformly distributing low-pressure steam (one atmosphere) in the cooking chamber. This is permanently mixed with cereals so that the product receives heat and pressure simultaneously and at the same temperature. Temperature sensors are placed in the system to avoid overheating or, conversely, insufficient cooking.

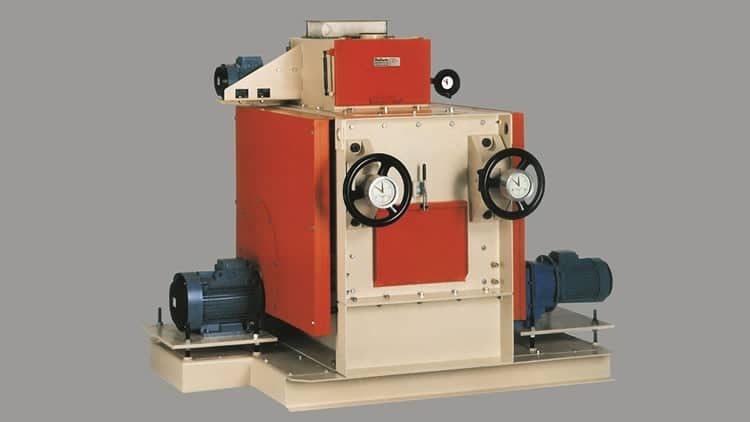

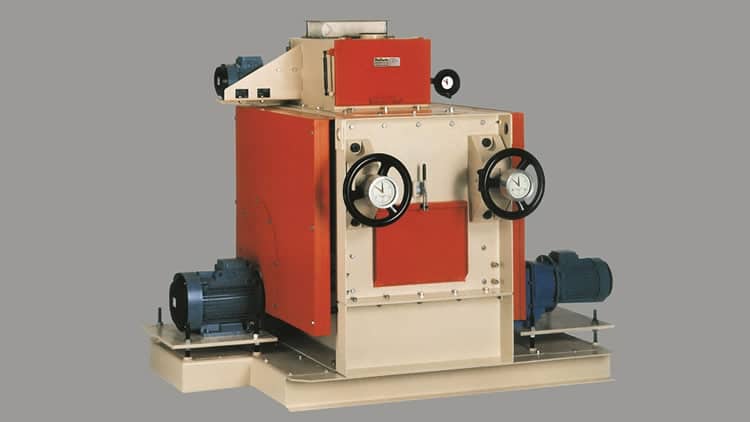

Phase 2: Mechanical Treatment.

This is done by a roller mill with two opposed cylinders. Uniform feeding across the entire rolling surface is crucial in this machine. It is possible to make a fine engraving on the crushing surface to facilitate flake detachment and thermal conductivity.

Phase 3: Drying and Cooling Treatment.

Moisture and temperature are removed in a dryer where the flaked product passes through currents of hot and cold air. Thus, a product with 13% moisture and a temperature close to ambient is obtained.

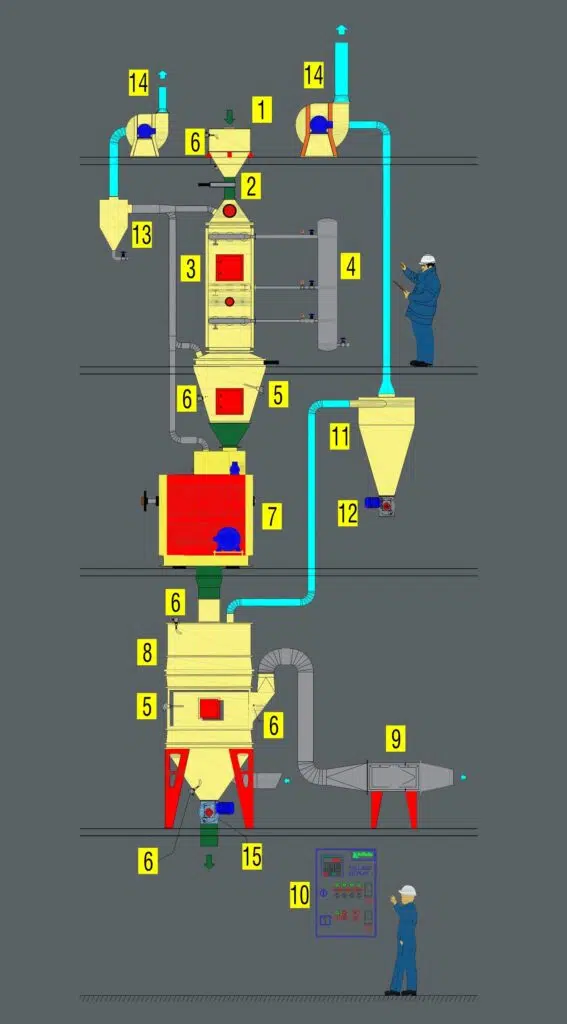

Grain Rolling Process Flow Diagram

01 – Feeding hopper

02 – Valve

03 – Phase 1: Steam cooker

04 – Steam frame

05 – Thermocouple

06 – Rotary level sensor

07 – Phase 2: Roller cylinders

08 – Phase 3: Cooler dryer

09 – Hot air generator

10 – Electrical board

11 – Cyclonic separator

12 – Extraction valve

13 – Steam condenser tank

14 – HT Fan

15 – HSC rotary valve

Types of Grains and Seeds for Rolling

- Wheat

- Corn

- Oats

- Rye

- Barley

- Rice

- Sunflower

- Chickpeas

- Soy

- Others

- Wheat

- Corn

- Oats

- Rye

- Barley

- Rice

- Sunflower

- Chickpeas

- Soy

- Others