Counterflow is the most efficient method to transfer heat to a mass of granulated product such as Grains, Feed, Pellets, Flakes, Petfood, Oil seeds, etc.

By precisely controlling the air flow rate and retention time, you can control the product discharge temperature and create conditions to maximize or minimize the moisture content in the final product.

The advantages of this type of vertical coolers are:

- It is possible to always have a more uniform temperature difference between the product and the air, thus increasing performance.

- It also minimizes product temperature shock and the product deterioration.

- The required layout footprint for the process is much smaller.

- Due to its design, there is a low risk of cross contamination between production runs.

- Using vertical gravity flow provides low mechanical complexity and low maintenance.

Possible configurations of vertical counterflow chillers

- Product and process specifications

- Requirements for quick-change-overs.

- Quick inspection and control needs.

- CIP cleaning.

- Fire detection and suppression, etc.

We build cooling lines, including cyclones, filters, fans, controls and automations. The ENC vertical counterflow chiller is one of our most important machines in the drying and cooling group.

Technical information

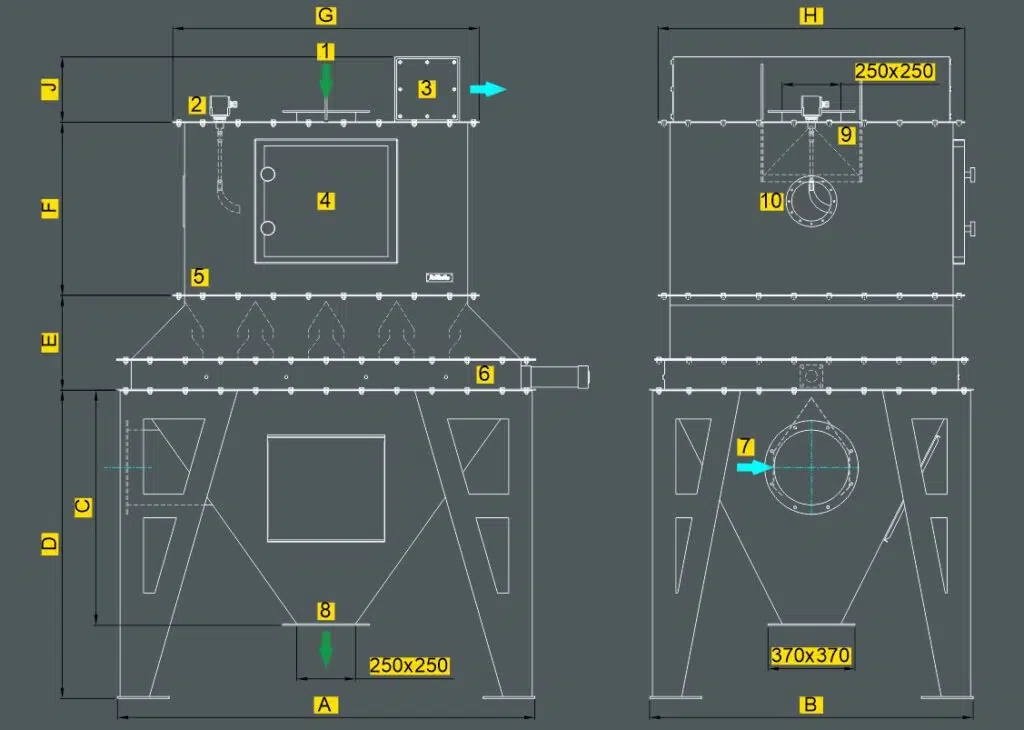

1 – Product entry

2 – Level control

3 – Suction duct

4 – Manhole

5 – Temperature exchange chamber

6 – Check valve

7 – Air inlet

8 – Download

9 – Rotating distributor (x)

10 – Viewer

(x) Only on ENC 300

1 – Product entry

2 – Level control

3 – Suction duct

4 – Manhole

5 – Temperature exchange chamber

6 – Check valve

7 – Air inlet

8 – Download

9 – Rotating distributor (x)

10 – Viewer

(x) Only on ENC 300

More information in the following links