Within the equipment for the transport of products, the modular downspout stands out, which is used for the transport of dry materials by taking advantage of the law of gravity.

The main advantage of our downpipes is precisely that they are modular. This allows a quick assembly by joining the different parts with rings and elbows.

Normally, control valves are coupled to the downspouts, which allow not only to verify that the product flow is correct, but also to take samples of the product for later analysis. All the pieces are manufactured with the following inner diameters: 100, 120, 150, 200, 250 and 300 mm. They can be manufactured in rustproof painted iron, as well as in stainless steel of normal or special thickness (indicated for the processing of abrasive products).

In the case of distributor valves, automation is possible by means of pneumatic actuators.

Technical information

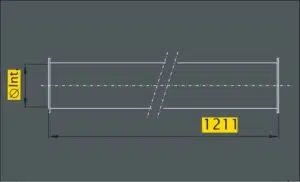

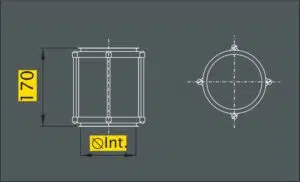

Welded pipe

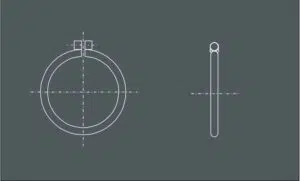

Pull ring

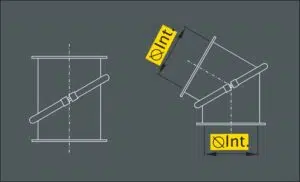

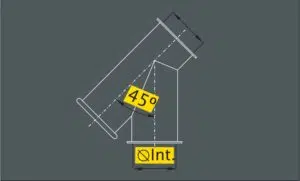

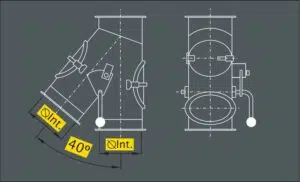

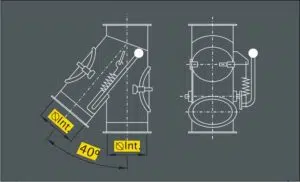

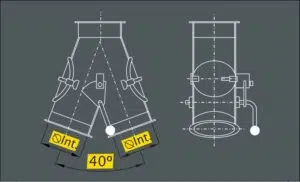

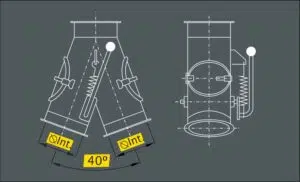

40/90 adjustable elbow

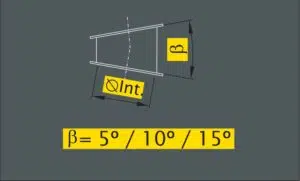

Elbow segment

SGRL Viewer

Grain buffers

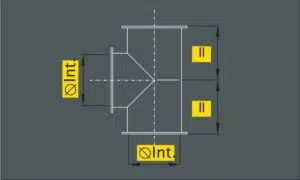

Inspection T Piece 90°

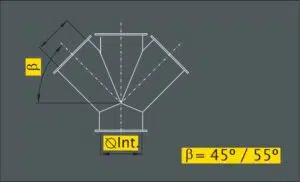

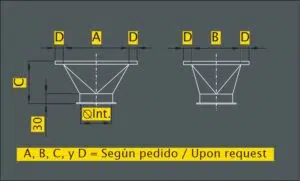

Symmetrical fork

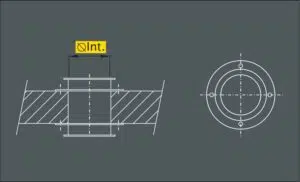

Inspection pipe

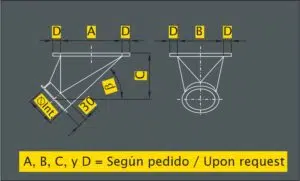

Double fork

Rubber cover

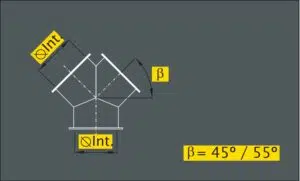

Asymmetric fork

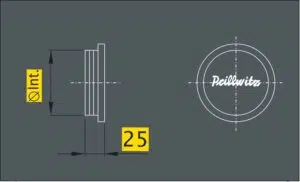

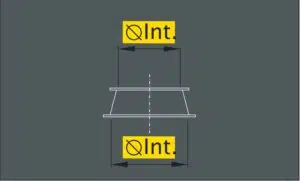

Connecting flange

Inclined discharge spout

Asymmetrical distributor

Cone piece

Asymmetric valve

Symmetrical distributor

Unloading spout

Symmetrical valve

All parts can be manufactured in the following inner diameters: 100, 120, 150, 200, 250 and 300 mm.

The products can be made of both anti-rust painted iron and stainless steel in normal or special thickness for abrasive products.

In the case of distributor valves, automation is possible through pneumatic actuators.

More information in the following links