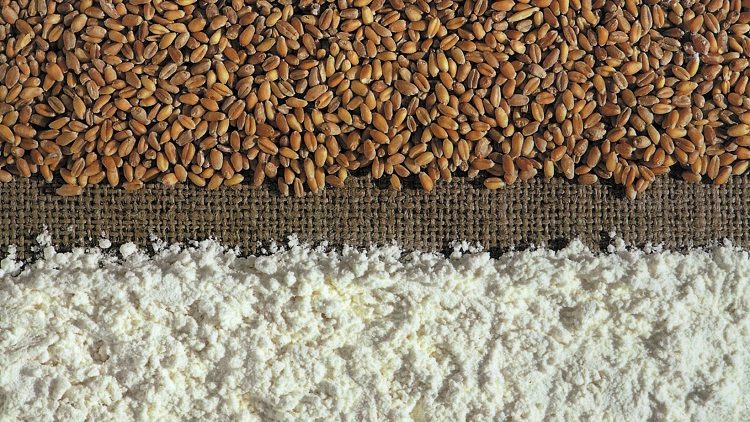

The machinery required for milling and sifting is fundamentally the same for different grains. The correct placement and utilization of these machines within the process flow is key to achieving high yields and a high-quality product.

As you know, the layout of machines in a soft or semi-hard wheat mill differs from that in a hard or durum wheat mill. The setup changes even more with other seeds like corn, rye, etc.

It’s also common to need to change sieving cloths when the quality of the same seed changes. In other cases, plansifter cloths must be changed to produce a different product. This is quite common in corn milling, where more grits may be required at the expense of corn flour, or vice versa. This, along with the quality of the machines, is something we are constantly working on in our engineering department.

Machines involved in milling wheat, corn, and other grains:

B Micronizing mill (Impactor)

B Micronizing Mill is specially designed to grind semolinas and other fine particles quickly and effectively, producing large quantities of flour without exposing the

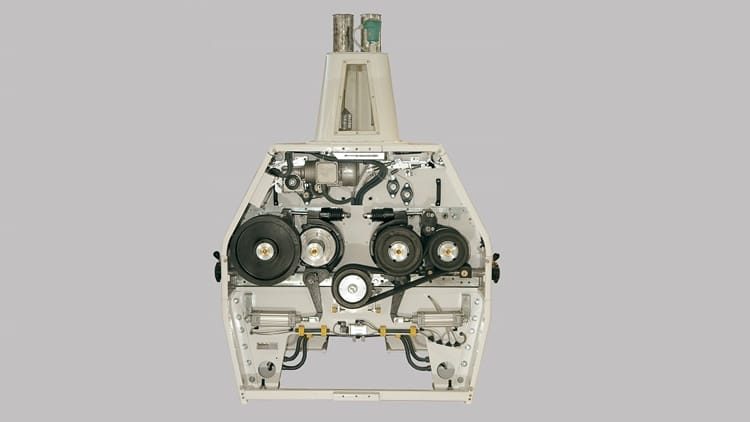

BCH roller mill

Double grain roller mill The BCH roll mill is the result of decades of research aimed at perfecting the grinding process, with the objective

CA Brushing Machine

Corn and bran brushing machine, plays an important role in the performance of the flour mill since, by the effect of the beating against

CDR reprocessing dosing sieve

Usable as a control sieve for both powdered and granulated products, this machine ensures the absence of foreign particles to re-enter the production line.

HDR detacheur

The HDR detacheur or dethatcher is used in grain milling to break up sheets of compacted product, which would be discarded in the sifting

HVS Centrifugal Sifter

HVS sifter has been designed to obtain maximum performance in the sifting of products that are difficult to sift, such as those coming from

Micrometric dispenser DMCA

The Micron metering feeder DMCA is used for micron metering of dry material. Our feeder has been specially designed to ensure accuracy and continuity

PA Impact detacher

PA breaker is used to break up flour flakes that would otherwise be mistaken for husks by the sifters and consequently discarded. On the

Plansichter or Plansifter

As the name suggests, this is a flat sifter. The sieve is in a perfectly horizontal position within a frame that supports it and

SGVM purifier

The sasor has proven its excellent performance in semolina cleaning and separation. Its fully adjustable system allows for excellent purity of the processed semolina.

TC Cylindrical Air separator

Air channel classifier-separator of light particles from heavier ones, within a flow of material that slides through the product to be treated. The tararas

Grains and products that can be processed with milling:

-

- Soft wheat or bread wheat

- Hard wheat or durum wheat

- Semi-hard wheat

- Flint corn

- Semi-flint corn

- Yellow corn

- White corn

- Oats

- Rye

- Barley

- Soybean

-

-

- Bran

- Fine bran

- Middlings and fine middlings of wheat

- Semolina

- Break flour

- Feed flour

- Corn semolina

- Wheat semolina

- Polenta

- Corn grits

- Wheat, corn, soybean, etc. flour

- Germ

- Starch

- Husks

-