They are mainly used for production control of dry bulk materials within the product flow in industries.

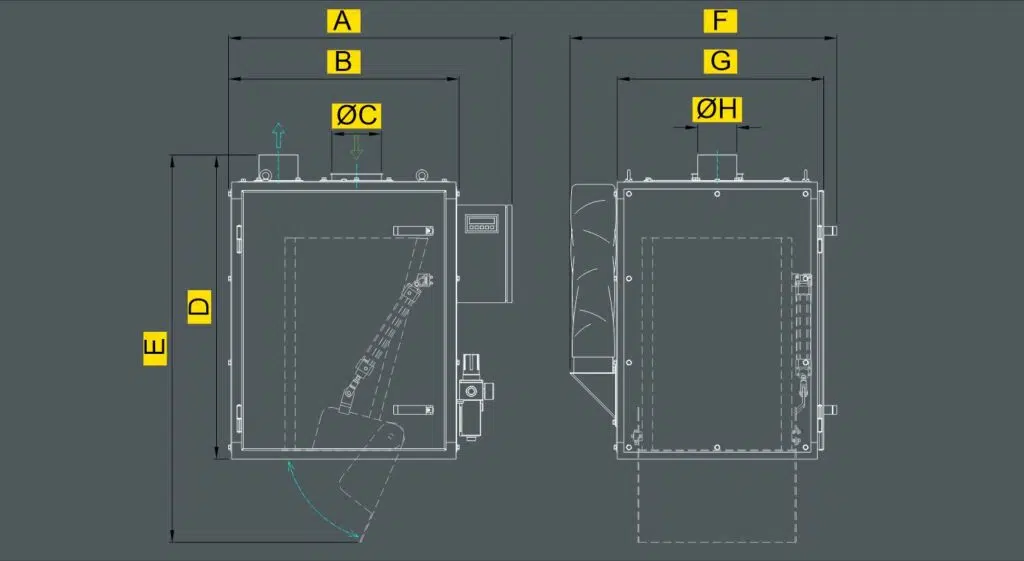

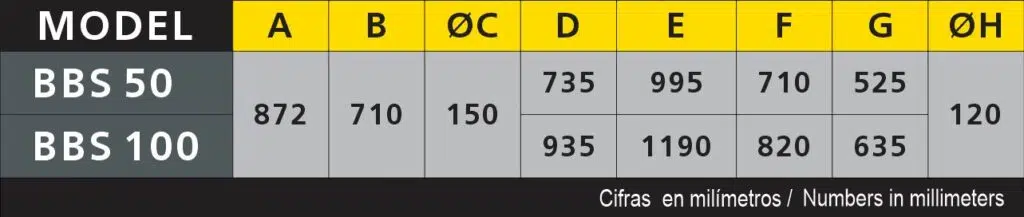

It basically consists of a vessel supported on load cells, with a feed valve and a discharge valve, both controlled by pneumatic actuators. This vessel is covered by a chassis with doors on its sides.

It has a control electronics that allows it to operate in 2 ways:

1- As a flow scale:

in this case, it requires an upper and a lower hopper, to accumulate product. Operating in this way, the operation cycle is as follows:

- The empty weighing vessel is tared.

- The loading gate is opened.

- When the loaded product reaches a predetermined weight value, the loading gate closes.

- The weight is checked and added to the accumulated weight.

- It is unloaded and the cycle is restarted.

2- As a bagging or batch scale:

In this case, an upper tank with a dosing element such as a screw conveyor is required. The operating cycle is as follows:

- The empty weighing vessel is tared.

- The signal is sent to start loading.

- When the weight reaches the preset value, the stop loading command is given.

- The weight is checked and added to the accumulated weight.

- If necessary, the parameter of the next weight cut command is corrected.

- Unload and restart the cycle.