Our coolers and dryers work under the counterflow principle, where the product descends vertically by gravity and the air flows in reverse through it.

By applying counterflow; the most efficient heat exchange principle for cooling or drying your product, you can ensure the lowest energy consumption per liter of evaporated moisture.

Applications of counterflow drying and cooling systems

- Food: Breakfast cereals, coffee beans, almonds & nuts, couscous, chocolate, etc.

- Feed: Pelleted, extruded, expanded, flaked, conditioned mash, etc.

- Petfood: Dry petfood kibbles, high protein and high meat petfood, co-extruded pockets, etc.

- Aquafeed: Extruded aquatic feeds, all sizes and each buoyancy, pelleted shrimp feed, etc.

- Oil seeds: Soya, rapeseed, sunflower seed, meal, pellets, cake, etc.

Its advantages are

- It is possible to always have a more uniform temperature difference between the product and the air, thus increasing performance.

- It also minimizes product temperature shock and the product deterioration.

- The required layout footprint for the process is much smaller.

- Due to its design, there is a low risk of cross contamination between production runs.

- Using vertical gravity flow provides low mechanical complexity and low maintenance.

Main components

Rotating distributor in product feeding

Continuous dryers and coolers can have as an option a rotating distributor and rake that can be adjusted in height to maintain an even product bed.

Continuous pulsed discharge system

Our innovative unloading system, commanded by pneumatic cylinders, allows the uniform flow of product and air.

HSC metering gate valve for discharge

The dosing valve prevents false external air from entering the dryer and ensures a consistent feed to downstream transport or coating systems without risking damage to the product.

Rotary airlock valves for pneumatic conveying, filter discharge, and metering

We manufacture high-quality rotary airlock valves, designed to meet the demands of various industries for handling powder or granulated products. Applications of rotary or

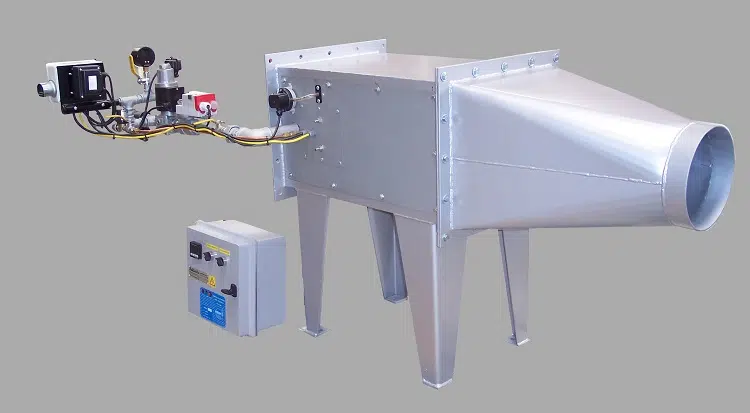

Hot air generators for dryers

When designing the air heating system for drying, the possibility of taking advantage of the already hot air from other processes such as that resulting from a cooler is taken into account. There are several alternatives to generate hot air and the most important are:

- Steam heaters

- Gas burners: for natural gas, propane, butane or biomethane.

GAGA hot air generator

Optional configurations

Prillwitz dryers and coolers are available in various models and configurations to suit your needs:

- Product and process specifications.

- Requirements for quick-change-overs.

- Quick inspection and control needs.

- CIP cleaning.

- With or without rotating distributor, etc.

Control and automation

By accurately controlling air volume and retention time you can adjust product discharge temperature and create conditions to maximize or minimize final product moisture content.

Common raw materials in this process:

- Wheat

- Maize

- Oats

- Coffee

- Cocoa

- Rye

- Beat

- Cheese

- Rice

- Girasol

- Chickpeas

- Rape

- Soybeans

- Peanuts

- Spices

- Balanced feed

- Pellets or feeds

- Crystalline sugar

- Impalpable sugar

- Cocoa

- Coffee

- Coriander

- Curcuma

- Gelatin

- Bone meal

- Flour

- Fish flour

- Milk powder

- Dried beans

- Breadcrumbs

- Batter

- Polycarbonate

- Vinyl polyvinyl chloride or PVC

- Polystyrene or PET

- Polyethylene

- Polypropylene

- Expanded polystyrene (Styrofoam)

- Sawdust

- Wood

- Cork

- Soap powder

- Pigments

- Wheat

- Maize

- Oats

- Coffee

- Cocoa

- Rye

- Beat

- Cheese

- Rice

- Girasol

- Chickpeas

- Rape

- Soybeans

- Peanuts

- Spices

- Balanced feed

- Pellets or feeds

- Crystalline sugar

- Impalpable sugar

- Cocoa

- Coffee

- Coriander

- Curcuma

- Gelatin

- Bone meal

- Flour

- Fish flour

- Milk powder

- Dried beans

- Breadcrumbs

- Batter

- Aluminum powder

- Atrazine

- Bentonite

- Borax powder

- Bentonite

- Lime

- Caolin

- Activated carbon

- Calcium carbonate

- Cement

- Shell

- Quartz

- Titanium Dioxide

- Dolomite

- Fertilizers

- Monoammonium Phosphate

- Diammonium Phosphate

- Tricalcium Phosphate

- Mica

- Refractory Materials

- Mica

- Sodium naphthalenesulfonate

- Fog black

- Pigments

- Soaps

- Salt

- Precipitated silica

- Caustic soda

- Magnesium sulfate

- Zinc sulfate

- Tanine

- Diatomaceous Earth

- Dyes

- Gypsum

- Lithium

- Polycarbonate

- Vinyl polyvinyl chloride or PVC

- Polystyrene or PET

- Polyethylene

- Polypropylene

- Expanded polystyrene (Styrofoam)

- Sawdust

- Wood

- Cork

- Soap powder

- Pigments