High precision fabrics from monofilaments for the filtration markets. They allow a very precise classification by size.

Depending on the need, there are different manufacturing materials and various types of fabric.

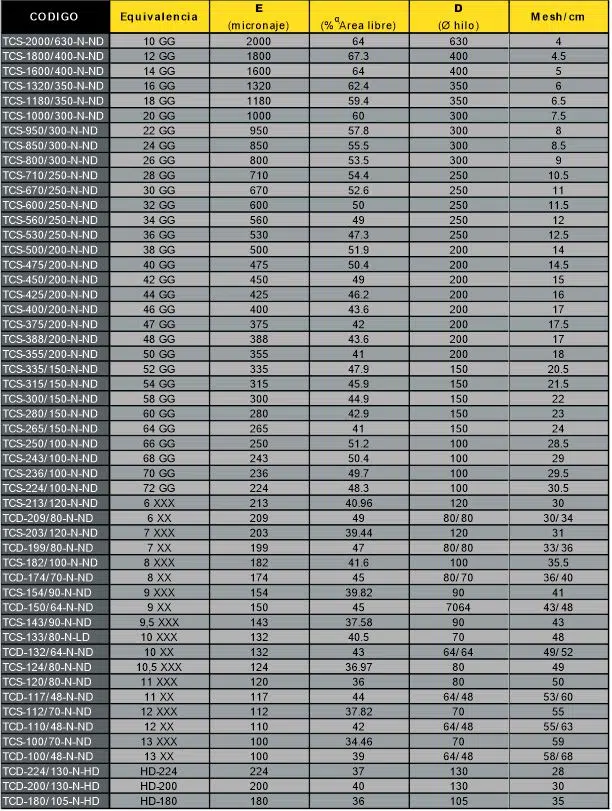

Main selection parameters of sifting fabrics

Type of fabric: According to how the sewing threads are intertwined, we have the following types;

- TCD – Double warp sifting fabric in one direction. Also called XX

- TCS – Single warp sifting fabric. Also called GG or XXX.

Mesh open: It is the free space through which the particle to be sifted can pass. It is usually measured in microns.

Thread diameter: Refers to the diameter or diameters of the clothing threads.

Material: Nylon (NY-Polyamide) is generally used, but it can also be made of other materials such as

- Polyester (PL)

- Polyethylene (PE)

- and steel (AC)

- or stainless steel (AI).

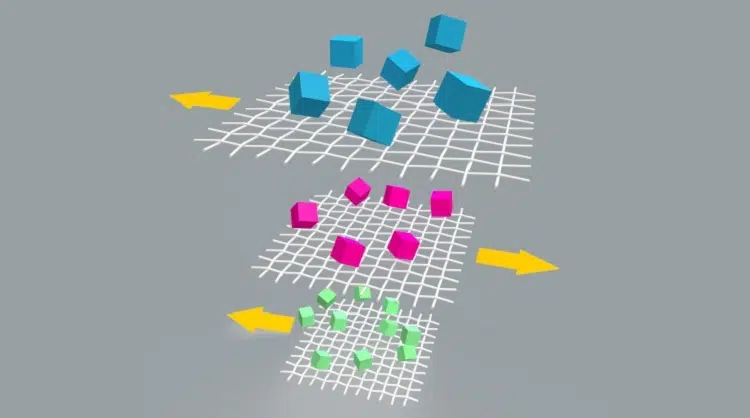

Wear resistance: By placing a wire with a larger diameter, more resistance is achieved but the sifting capacity is lower.

- Light duty (LD) – Fine wires and high sifting performance

- Normal duty (ND) – Medium resistance and sifting performance

- Heavy duty (HD) – High wear resistance

Coding example: TCD-2000/630-NY-ND

Parameters that determine a fabric for screening

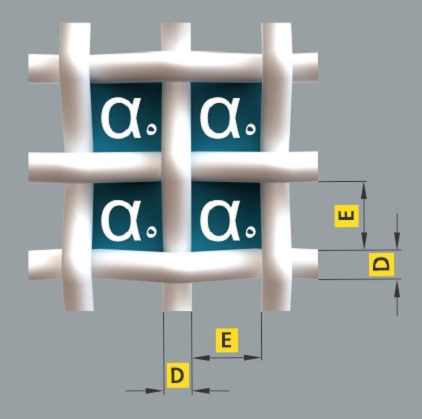

- Nominal wire diameter d (µm). The diameter of the yarn is measured on the strand before weaving.

- Mesh opening E (µm). The mesh opening E is the distance between two adjacent horizontal and vertical strands.

- Open area α۪(%) Open area percentage α۪is the sum of all mesh openings as a percentage of the total fabric area.

Its main application is in machines for classification and sifting. There are cylindrical types such as the HVS centrifugal sieve or flat types such as the Plansichter.

Classifying and Sifting

We offer many types of sifters that adapt to the type of product and the need for classification or screening. Some of them are […]