The correct conditioning or cleaning of grains is essential for their subsequent milling. Its function is fundamentally the separation of foreign bodies and the moistening of the grain.

We would like to emphasize that when designing each of the machines that make up the sector, we pay close attention to their cost and energy consumption in relation to the efficiency of their work.

In this way, our cleaning processes will never include unnecessary machines. It is important to note that there is no single machine that can do all the work for grain cleaning, meaning the cleaning process involves a series of different attempts to achieve the desired outcome.

Machines involved in the cleaning of wheat, corn, and other grains:

- Pre-cleaning: Also known as preliminary cleaning, this step is carried out before sending the wheat to the mill. The main goal here is to separate products larger than the grain to be milled. This is done with our CPLG screen. If there is a need to also separate small particles, husks, and dust, the RSVM sieve with its air channel or tarara can be used.

- First cleaning: This is the first cleaning done in the mill and before the grain is moistened. Machines used in this stage include the RSVM sieve, the RHS scouring machine, the SDA disc separator, the DAGH water doser, among others.

- Second grain cleaning: This occurs after moistening and usually involves a RHS scourer or huller, which removes small husks that were loosened in the rest silos, significantly reducing potential contamination issues. To monitor production and yields, we also recommend adding a flow control scale at this stage.

Machines involved in the cleaning of wheat, corn, and other grains

BBS continuous flow or batch scales

They are mainly used for production control of dry bulk materials within the product flow in industries. It basically consists of a vessel supported

CPLG industrial screen for grain cleaning

Horizontal drum screen CPLG horizontal drum screen is used for separation sieving of particles coarser than the product flowing from it. It has a

DAHG Humidifier Doser

Grain wetting, essential in the milling and sifting processes, consists of 2 stages: water dosing on the one hand and mixing with the grain

DMB volumetric meter

DMB volumetric meter is used to extract constant hourly volumes of product from storage silos. Thus, by placing several volumetric meters in different hoppers

DPR gravimetric destoner

DPR gravimetric destoner has bee designed to separate the light and heavy fractions of grain and to partially remove dust and impurities. It is

HSR Indented Cylinder

Grading by form: Mechanical separation by indented cylinders is used for grading any granular material such as wheat, corn, oats, etc. by form and

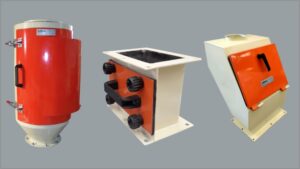

Magnetic separator

We have different types of magnetic particle separators that adapt to each type of product and application. To control foreign particles from a material

RSVM sieve shaker

The RSVM Shale Shaker, is designed for the cleaning or classification of cereals or other products, allowing the separation of impurities and foreign objects of

Scourer

The shellers are used in the cleaning stage to remove undesirable particles (such as hulls, dust and sand) from the wheat kernels, conditioning them

SDA Grain Classifier

Specially designed for an efficient separation of grains according to their shape, the SDA Separator guarantees a perfect classification of an infinite number of

SIGMA hammer mill

Versatile industrial hammer mill Designed to provide high efficiency and versatility in crushing and grinding processes, it finds application not only in the grinding

Products and grains we can process with cleaning:

-

- Soft wheat or bread wheat

- Hard wheat or durum wheat

- Semi-hard wheat

- Flint corn

- Semi-flint corn

- Yellow corn

- White corn

- Oats

- Rye

- Barley

- Soybean

-

-

- Bran

- Fine bran

- Middlings and fine middlings of wheat

- Semolina

- Break flour

- Feed flour

- Corn semolina

- Wheat semolina

- Polenta

- Corn grits

- Wheat, corn, soybean, etc. flour

- Germ

- Starch

- Husks

-