We manufacture high-quality rotary airlock valves, designed to meet the demands of various industries for handling powder or granulated products.

Applications of rotary or airlock valves

The main applications are:

- To allow the passage of a dry powder or granulated product between two environments at different pressures without allowing air to pass through. This is a common application in pneumatic conveying systems for introducing or extracting the product from the system or in bag filter discharge.

- To meter the flow of product from one container or environment to another. In many cases, it is necessary to feed or discharge a system in a controlled manner, which can be achieved by adjusting the rotation speed of the rotary airlock valve. This is just one of the possible machines for this function of dosing dry products.

- The third application combines the previous two applications.

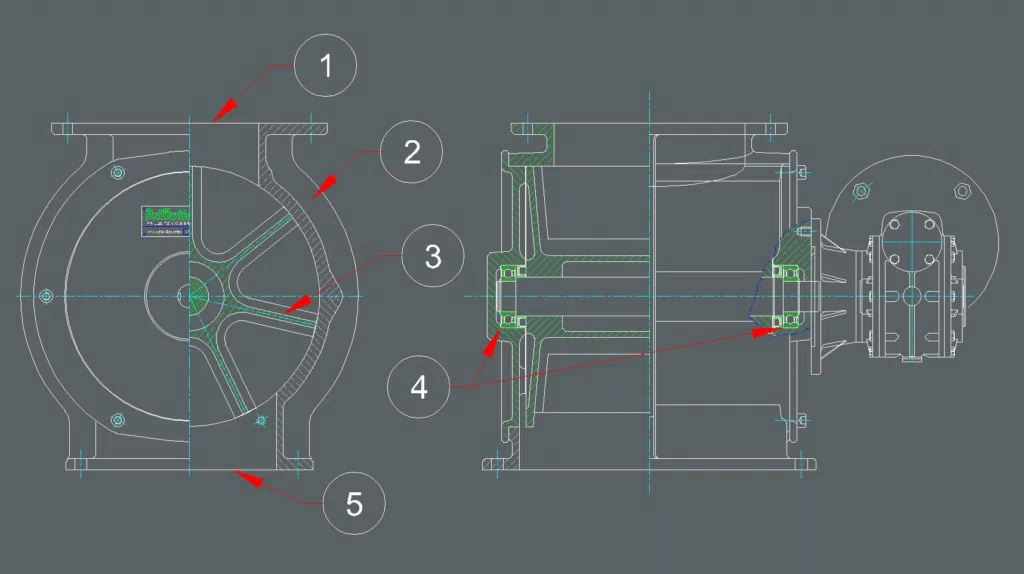

Operation of a rotary valve: Main components

A rotary or airlock valve primarily consists of the following components:

- Inlet

- Body

- Rotor

- Bearings and labyrinth seals

- Discharge outlet

Types of rotary valves or sluices

We offer a wide range of rotary sluices, including the following models:

- Vertical rotary extraction valve HSD: Primarily designed for discharge from pneumatic transport systems or bag filters. Also useful for general dosing.

- Horizontal rotary valve HSP: Specifically developed for feeding powder pneumatic transport systems.

- HSG rotary airlock valve: Designed for handling dry granular products where cutting the product with its blades can be an issue.

- HSC rotary airlock valve: This model is used for products that should not be damaged by shearing. Due to its construction type, it does not allow for isolation in environments with high pressure differentials.

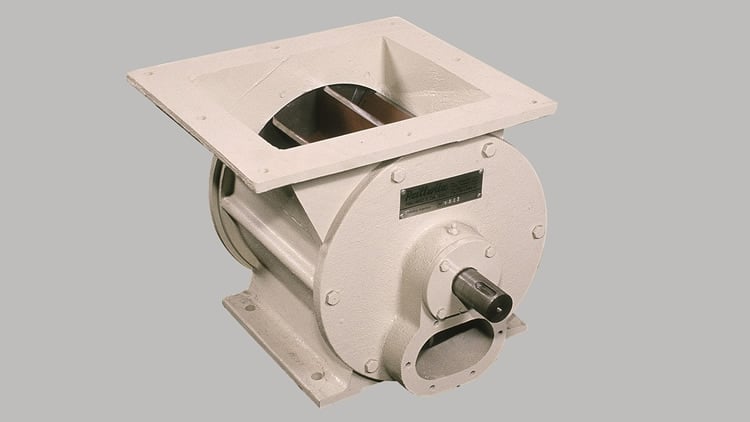

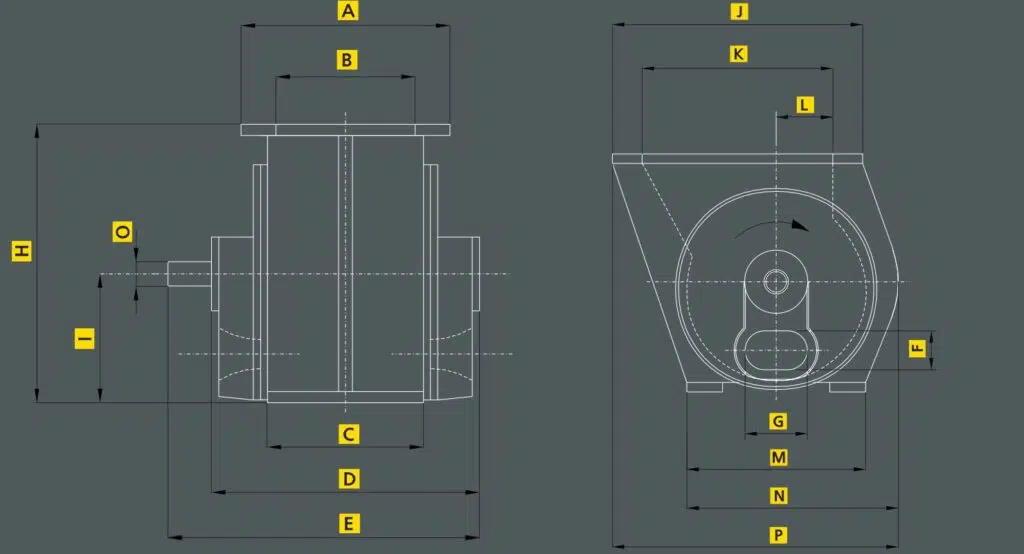

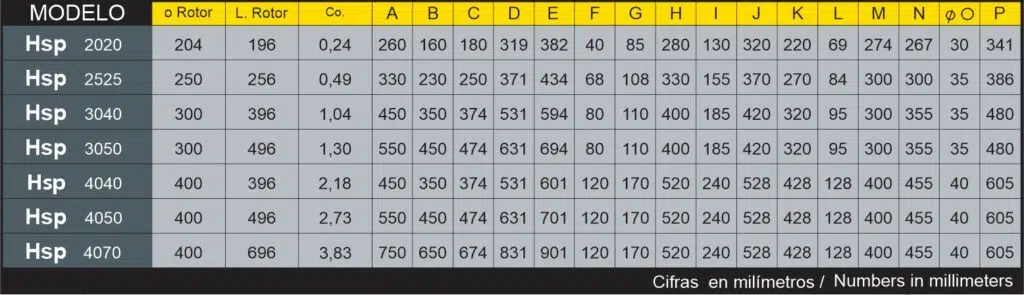

1- Válvula esclusa rotativa de extracción o paso vertical HSD

The HSD vertical extraction valve is a dust control system used as a seal in the discharge of pneumatic transport systems, below air filters and cyclones, or as a dosing medium for silos, containers, and storage hoppers. Thanks to its precise construction, our HSD discharge sluice functions perfectly under both vacuum and positive pressure, ensuring complete sealing of the product being discharged.

Rotary extraction sluices are critical components in any industry processing granular or powdered products—such as milling, chemical, and plastics industries—integrating pneumatic transport and dust control systems and collaborating with feeders and dosers in the production line.

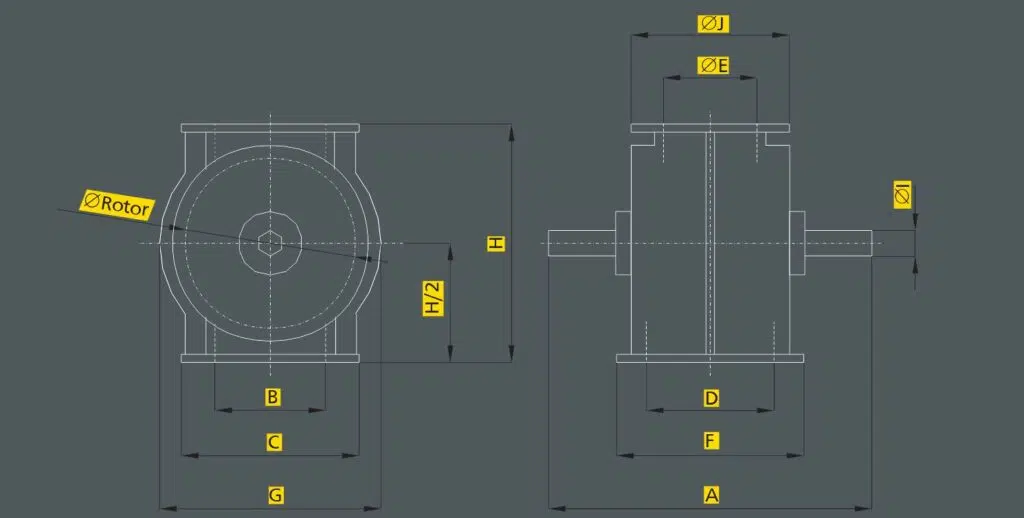

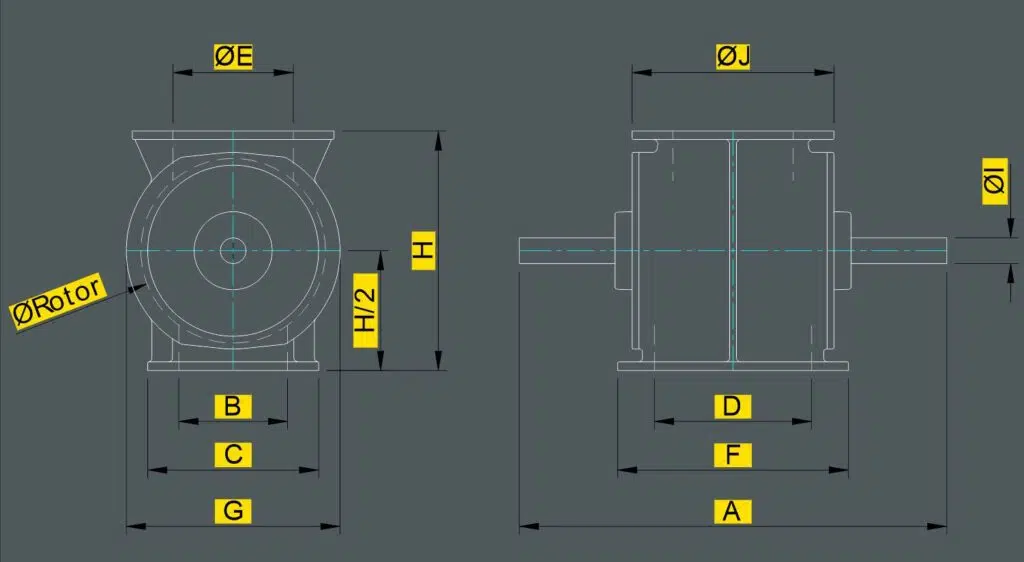

Technical information

Calculations

Capacity (Ton/h) = Co x ρ x n x α / 100

Where:

Co (m³/h x r.p.m) = Capacity with 100% fill percentage for 1 r.p.m. See table.

ρ (Ton/m³) = Specific weight

n (r.p.m) = Revolutions per minute

α (%) = Valve fill percentage

More information in the following links

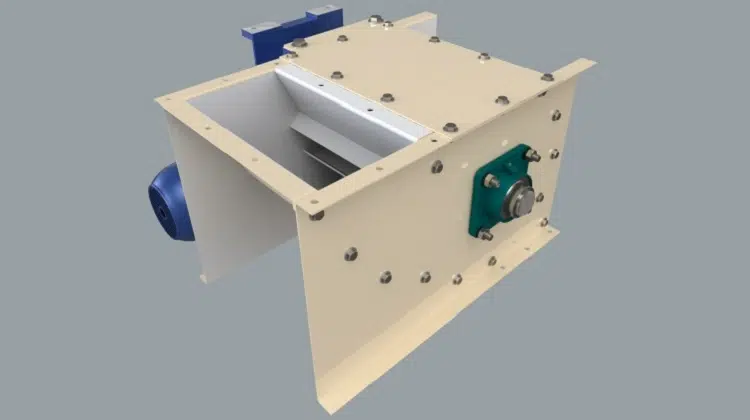

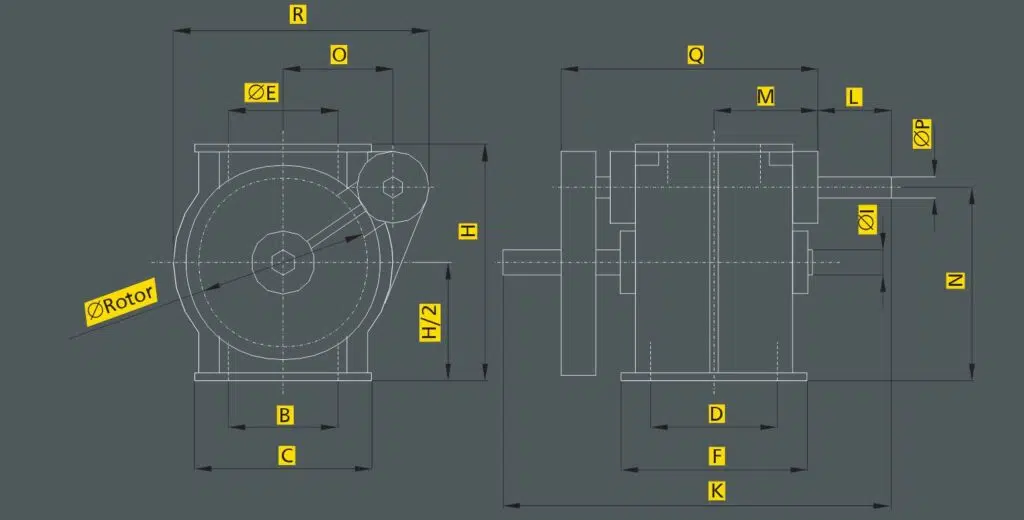

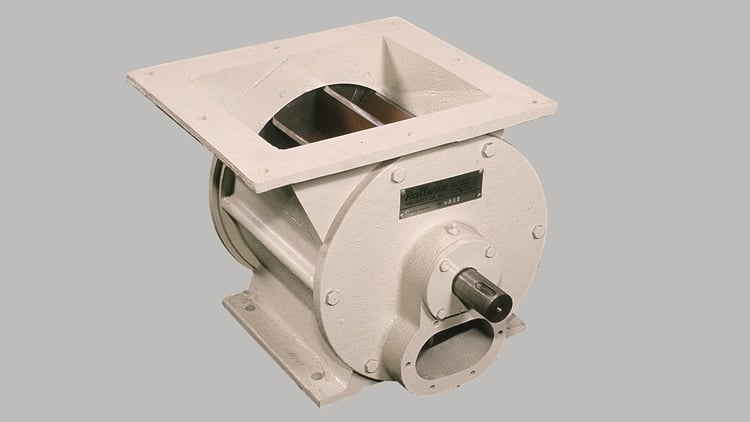

2- Horizontal rotary valve HSP

Specifically designed for product admission in a horizontal flow in pneumatic transport lines, the HSP rotary valve allows for an ideal mixture of the product with the air present in the transport pipes. Its robust construction provides great resistance and the capacity to withstand high pressures without wearing out. Moreover, the precision of its machining ensures perfect airtightness and sealing.

Although normally manufactured in cast iron, we have special rotary airlocks, with internal chrome plating and hardened rotor, for handling abrasive products.

Our inlet valves are used in various industries – milling, chemical, plastic, food, etc. either integrating pneumatic conveying systems, dust control systems and collaborating with product feeders/dosers to the production line.

Technical information

Calculations

Capacity (Ton/h) = Co x ρ x n x α / 100

Where:

Co (m3/h x r.p.m) = Capacity at 100% fill rate for 1 r.p.m. See table.

ρ (Ton/m3) = Specific weight

n (r.p.m) = Revolutions per minute

α (%) = Valve filling percentage

More information in the following links

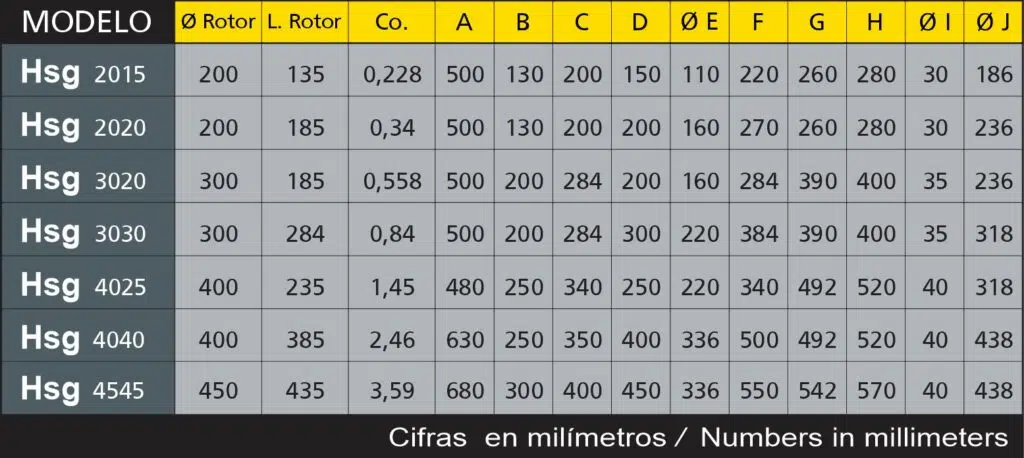

3- HSG rotary sluice valve

Like any rotary airlock valve, its function is to allow the flow of the product, without letting the air escape. This model is designed to also not allow the shearing or cutting of the product with the valve blades.

This valve can be used not only a sealing in the pneumatic transport’s discharge or under dust collectors, but also as a dosing media for bins. Due to its precise construction, the HSG valves ensure absolute tightness and reliance.

This valve is absolutely adequate for Its use in negative and effective pressure. It can be placed under dust collectors, air separators or bins.

Construction details of HSG rotary lock valve

- The body and rotor are normally made up of cast iron and the shaft of carbon steel, mounted on bearings.

- However, it can be also produced in stainless steel or other materials.

- A perfect and lasting sealing is ensured due to Its exact machining.

- Special execution with chromed interior and hardened rotor for abrasive products.

This type of rotary valve is one of the 4 types of valves we have for pneumatic conveying systems. Because it does not allow shearing or cutting of the product with the valve blades, it is especially used in the dosing of granulated products such as those used as raw materials in the plastic industry. For example, polycarbonate, polyvinyl chloride or PVC, polystyrene or PET, polyethylene, polypropylene, etc.

Technical information

Calculations

Capacity (Ton/h) = Co x ρ x n x α / 100

Where:

Co (m3/h x r.p.m) = Capacity at 100% fill rate for 1 r.p.m. See table.

ρ (Ton/m3) = Specific weight

n (r.p.m) = Revolutions per minute

α (%) = Valve filling percentage

More information in the following links

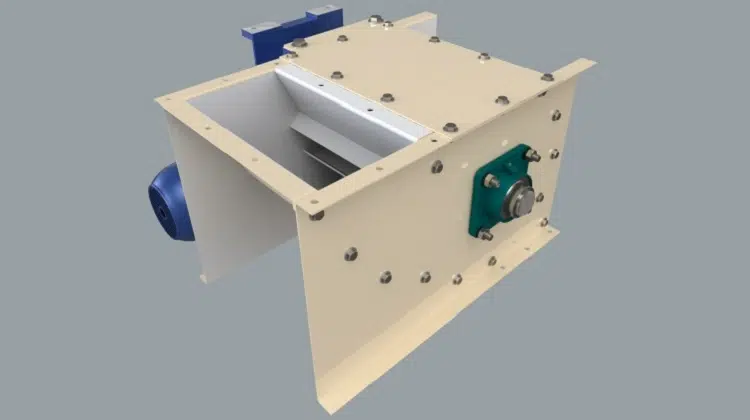

4- HSC rotary sluice valve

Like any rotary airlock valve, its function is to allow the flow of the product, without letting the air escape. This model is designed so as not to deteriorate the size of the product particles.

Its main application is for products that must be handled delicately and do not want to break or deteriorate, such as grains, feed or pellets, flakes, balanced food, pet food, etc.

Made of steel or stainless-steel sheets, which does not allow it to be used with high pressures.

Taking into account that it is designed mainly to not deteriorate the size of the product particles, our HSC rotary lock valve has among its most notable applications its use in the discharge of dryers and coolers.

Drying and cooling feed and food

We build cooler and dryers lines, including their cyclones, filters, fans, controls and automation. Our coolers and dryers work under the counterflow principle, where

Technical information

Calculations

Capacity (Ton/h) = Co x ρ x n x α / 100

Where:

Co (m3/h x r.p.m) = Capacity at 100% fill rate for 1 r.p.m. See table.

ρ (Ton/m3) = Specific weight

n (r.p.m) = Revolutions per minute

α (%) = Valve filling percentage

More information in the following links