Grading by form: Mechanical separation by indented cylinders is used for grading any granular material such as wheat, corn, oats, etc. by form and for separating them from stalks and other long or short straws.

They can be used alone or set in series to accomplish different jobs identifying different types of impurities.

The most important thing: The quality of the triarvejones alveoli

The alveolated cylinders are the most important part of the triarvejón. The quality of the separation and the volume of waste will fundamentally depend on their design. For this reason, we give special importance to the quality of their design and manufacture.

Each cylinder has only one type of alveoli, but the alveoli can be of many different diameters and shapes. Therefore, for each type of separation required, a set of cylinders will need to be chosen or several placed to select different shapes simultaneously.

Grain sizes can vary between 1.0 and 24 mm.

Operating principles of the alveolated cylinders:

It is essentially a horizontal rotating cylinder with alveoli or receptacles on its inner surface.

- After passing through the cylinder inlet, the granular material to be classified flows into the rotating cylinder.

- Grains shorter in length than the diameter of the alveoli are lifted and fall into the internal tray and are discharged by a screw conveyor.

- Longer grains remain in the cylinder and are discharged at the end, separately.

They are used to classify all kinds of granular materials by length, as well as to extract different foreign or unwanted products. They are widely used for wheat, oats, corn, rice, fine seeds, lentils, sunflower seed stems, sugar beets, plastic particles, etc

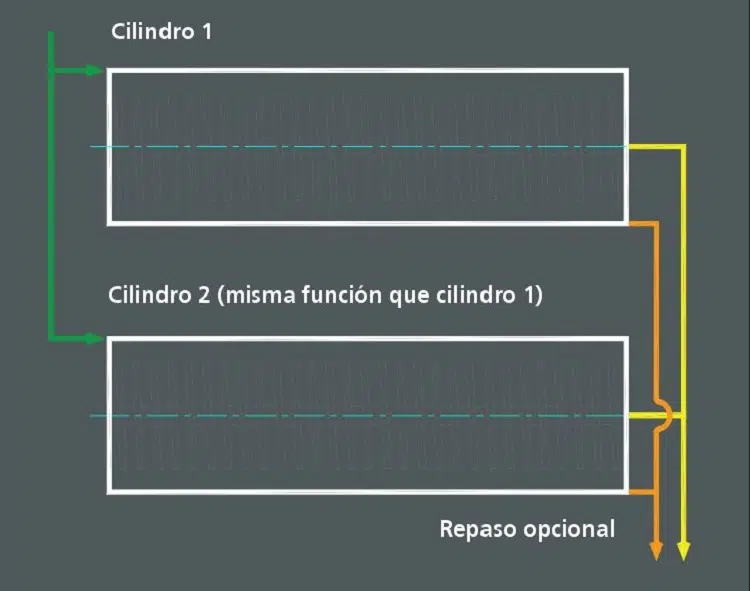

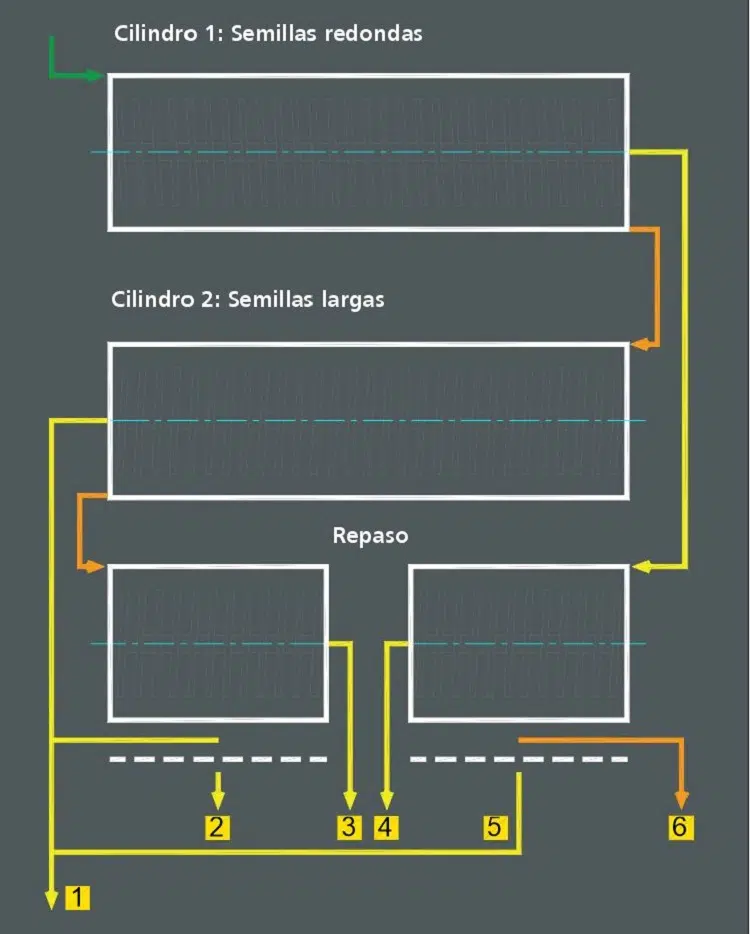

Typical Flow Charts:

The indented cylinders can work in series, focusing on different results so to maximize product sorting:

In all cases, placing regrader cylinders is optional.

The usual setup for grain cleaning in wheat flour mills involves cylinders in series with finishing cylinders to increase yield.

1-Good product

2- Thin grain

3- Long grain

4-Cockles and broken kernels

5-Small grain (Good)

6- Vetches