Pneumatic solid transportation systems are currently considered one of the most effective means for product transportation due to their safety, hygiene, precision, and reliability. Pneumatic conveying is the solution to numerous challenges posed by product movement.

Adaptable to any capacity and length requirement, this technology significantly simplifies the transfer of products between production sectors. With extensive experience in the application of this system, Prillwitz specializes in pneumatic conveyor application for a wide variety of products, employing specific techniques for each.

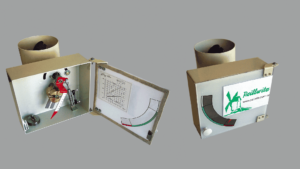

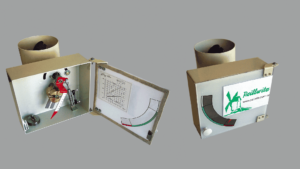

Example diagrams with options for vacuum pneumatic transport (Negative Pressure) and pressure transport (Positive Pressure)

03- Centrifugal Fan

04- Rotary Valve

05- Venturi

07- Product Viewer

08- Air Filter

09- Damper Box

10- Level Sensor

11- Storage Bin

12- Discharge Valve

13- Inlet Shoe

14- Sterilizer

15- Inline Sieve

Combined parallel vacuum pneumatic transport system

When several pneumatic transports are desired with a single air generator, the parallel vacuum pneumatic transport system is used.

Widely used in flour mills, where each product from the milling process is independently elevated. Our HT fans are commonly used as air generators.

01- Inlet boot

02- Transport duct

03- Viewer

04- Conicel cyclone

05- SGS viewer

06- HSD discharge rotary valve

08- Manual butterfly valve

09- HT fan

10- Bag filter

11- Electropneumatic butterfly valve

In this type of system, when the load (kg/h) of one of the ducts decreases, the air tends to flow more through it, decreasing in the others. This can cause a blockage in the transport of some ducts. To prevent this, VAR self-regulating valves are placed on the cyclones

Self-adjusting valve for pneumatic suction conveying VAR

Ideal for lowering energy consumption in the pneumatic parallel suction conveying system This valve is employed as a substitute of non-self-adjusting valves that are

Which machines can generate air for pneumatic transport?

Air can be generated using a regenerative turbine, a rotary lobe blower, or high-pressure fans.

Three-lobe rotary blower ASR3 – type Roots

We have been supplying compressors for more than 60 years, when we started representing Aerzen of Germany. The 3-lobe rotor blowers of the ASR3

Regenerative turbine Blower

Regenerative turbine Blowers or side channel blowers are reliable and efficient equipment used for different applications, mainly for pneumatic transport, with flow rates up

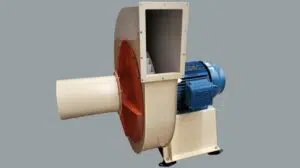

HT high pressure centrifugal fan

HT high pressure centrifugal fans have been designed trying to achieve the highest possible performance in applications where high air flow rates are required

Necessary accessories for pneumatic transport systems

Among our accessories for pneumatic transports, the HSP rotary valves, HSD discharge rotary valves, and HSG rotary valve stand out, ensuring airtight product loading and unloading. VTN and VTNGa valves allow the pneumatic transport lines to be diverted to different discharge points.

Rotary airlock valves for pneumatic conveying, filter discharge, and metering

We manufacture high-quality rotary airlock valves, designed to meet the demands of various industries for handling powder or granulated products. Applications of rotary or

Diverter valve for pneumatic conveying

In many pneumatic conveying systems, it is necessary to transport the product to multiple destinations. For this, our diverter valves are used. 1- ASR3

Self-adjusting valve for pneumatic suction conveying VAR

Ideal for lowering energy consumption in the pneumatic parallel suction conveying system This valve is employed as a substitute of non-self-adjusting valves that are

Air-to-air cooler for pneumatic transport

In the case of pressure pneumatic transport using a rotary piston compressor to generate air, a significant increase in air temperature occurs.

Thus, for some heat-sensitive products, it is advisable to use an air-to-air cooler.

Some examples of products requiring it:

- Sugar: High temperature causes it to stick to pipes and other transport elements.

- Some plastics or resins: The temperature can deteriorate the product and form long strands or “angel hair” when it strikes transport elements or itself.

Frequently Asked Questions

A pneumatic conveying system is a way of moving a bulk dry powder or granular product by mixing it with a gas, typically air, which carries it through a pipeline.

In dilute phase pneumatic conveying, particles slide through ducts at high speed with a large amount of air at low pressure. It can be either pressure or vacuum driven.

Vacuum pneumatic conveying, or suction conveying, is an efficient way to move solids in grain or powder form, which are fluidized by the air generated by the vacuum pump. They then flow freely through the pipes to their destination.

It is used across industries for the movement of powders and granules. It has several key advantages over mechanical conveying systems such as screw conveyors or bucket elevators.

1-It allows for transportation routes of highly variable geometry, without the limitations of the mentioned systems, which generally only allow for horizontal and vertical transport.

2-It leaves the installation much cleaner of residue from the transported product, upon completion.

3- It takes up less space and is cleaner for the surrounding environment, as it is a closed system.

The advantages of dilute phase pneumatic conveying include flexibility for transfer in limited or small spaces, dust suppression in the environment, and easy maintenance.

Among the advantages of vacuum conveying are dust suppression and leak containment. It can also be applied in explosive atmospheres, with secure and graceful receivers, adapting the system to customized demands.

Thanks to their experience in implementing pneumatic and mechanical transport systems, Prillwitz has the technical knowledge necessary to adapt the various machinery to the specific characteristics of the product being handled.