For the rice industry and rice mills, we have machinery to address various aspects of your needs.

Processes in the rice industry where we can assist:

- Rice Grain Classification: We have sieves, SDA disc separators, and BPM single-channel sifters.

- Milling Installations: We also provide milling installations for by-products or to produce micronized rice. We have complete milling and sifting systems that will allow you to achieve the desired granulometry.

- Secure Storage: After generating the final product, it is essential to store it securely. We also specialize in the construction of special silos with different types of extractors.

- Conveying: To ensure the rice reaches the final consumers, it must go through multiple processes, including conveying. Therefore, we also manufacture pneumatic and mechanical conveying systems, bucket elevators, and HSF screw conveyors.

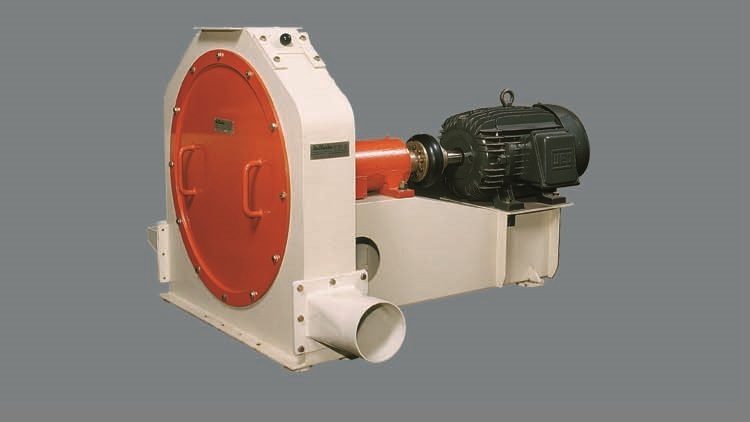

- Clean Processes: To achieve environmentally friendly and operator-safe processes, we manufacture modern air suction and filtration systems, including cyclones, fans, and HDF bag filters for dust extraction and control.

- Correct Preservation: We guarantee the correct preservation of the product until it reaches the final consumer, providing the right equipment for proper packaging in bags or big bags.

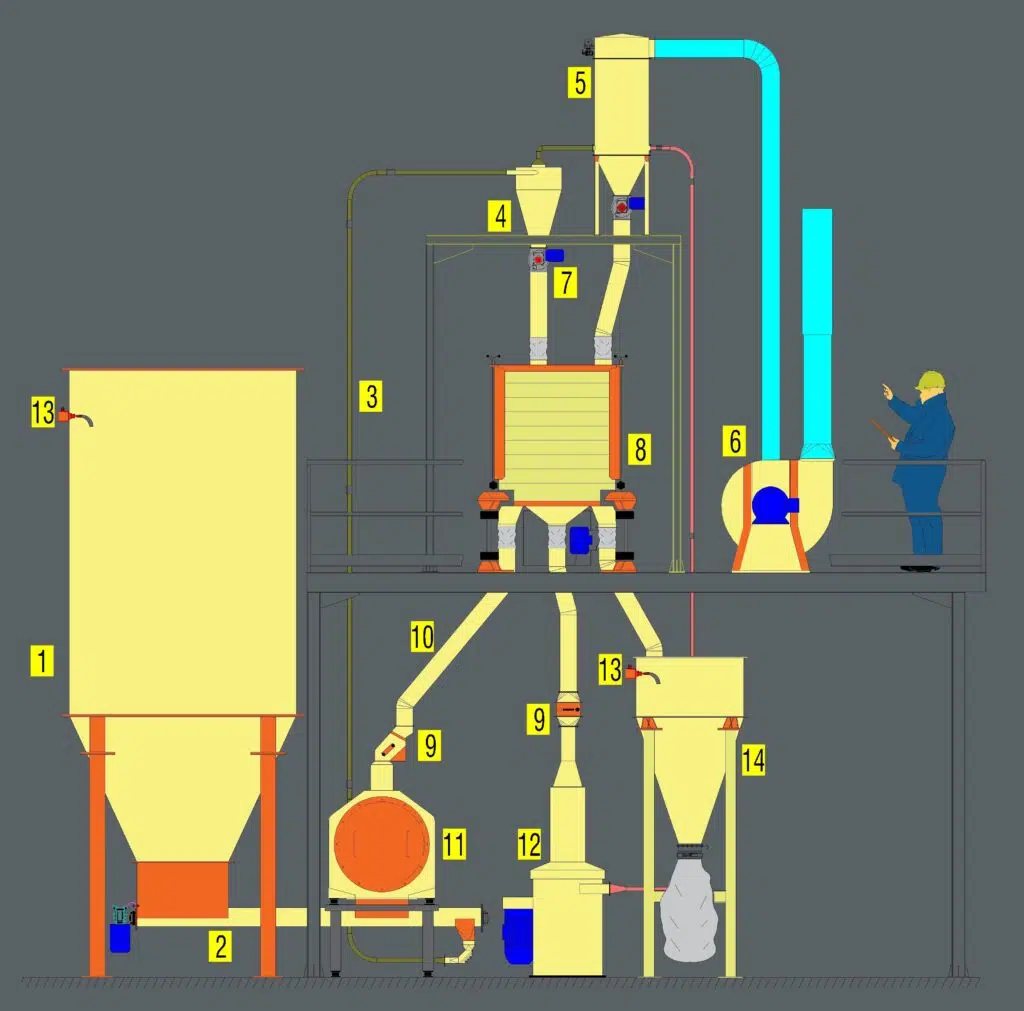

Typical micronized milling process to produce rice flour

To manufacture light rice cakes and other types of snacks, it is necessary to start with ground or micronized rice. Generally, rice bran is used as raw material. With our milling and classification installations, we can achieve the proper granulometry and precision for each type of need.

04-Cyclonic separator

05-Air filter

06-Fan

07-Rotary valve

08-Plansifter

09-Magnet

11-Hammer mill

13-Level sensor

14-Deposit hopper