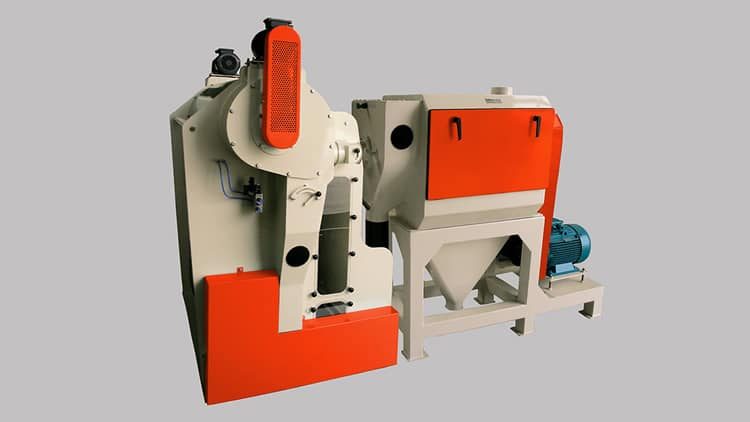

The shellers are used in the cleaning stage to remove undesirable particles (such as hulls, dust and sand) from the wheat kernels, conditioning them for subsequent milling.

The product, which enters tangentially to ensure a good yield, is treated by friction caused by the centrifugal action of the rotor beaters against the jacket. In this way the fine particles pass through the liner. The separation between the rotor and the jacket has the great advantage of being adjustable, thus achieving optimum performance. The machine has doors on each side, which gives it the advantage of having a liner that covers almost the entire circumference, compared to others that have much smaller liners.

The set formed by the trough and the decanting chamber are the ideal complement for this machine, since they allow the correct elimination of the separated particles that could not pass through the perforated plate.

The trough circulates air through a thin film of wheat, taking with it the light particles of which all except the dust fall into a channel of the settling chamber and exit to one side of the machine through a system of oscillating valves. The suction is adjustable through another valve.

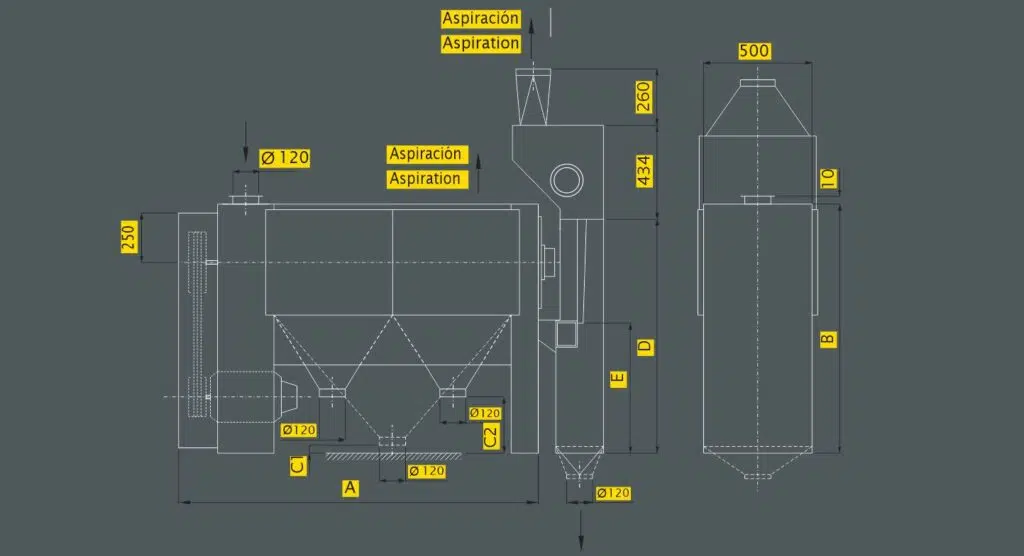

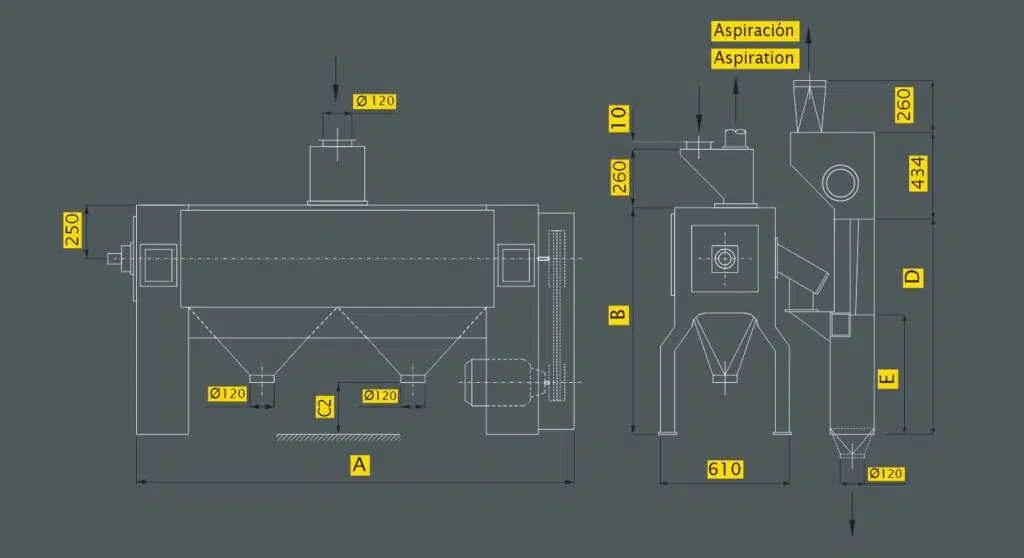

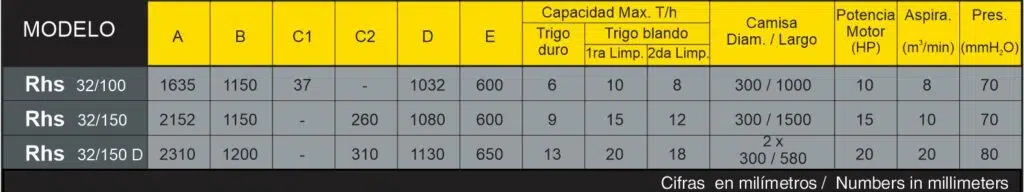

Technical information

Simple Versión

Double Versión

More information in the following links