Counterflow is not only the most efficient method to transfer heat, but also moisture.

When combined with the recovery and reuse of energy from the cooler, counterflow dryers can achieve tremendous energy savings.

Main advantages of the SVA vertical counterflow dryer

- It is possible to always have a more uniform temperature difference between the product and the air, thus increasing performance.

- It also minimizes product temperature shock and the product deterioration.

- The required layout footprint for the process is much smaller.

- Due to its design, there is a low risk of cross contamination between production runs.

- Using vertical gravity flow provides low mechanical complexity and low maintenance.

Possible configurations of vertical dryers

- Product and process specifications

- Requirements for quick-change-overs.

- Quick inspection and control needs.

- CIP cleaning.

- With or without rotating distributor, etc.

Precise control of drying time and drying air flow, temperature and relative humidity ensures the best humidity uniformity and energy efficiency. Advanced PLC controls allow a fully automated process, and use individual recipes for each product. The SVA vertical counterflow dryer is one of our most important machines in the drying and cooling group.

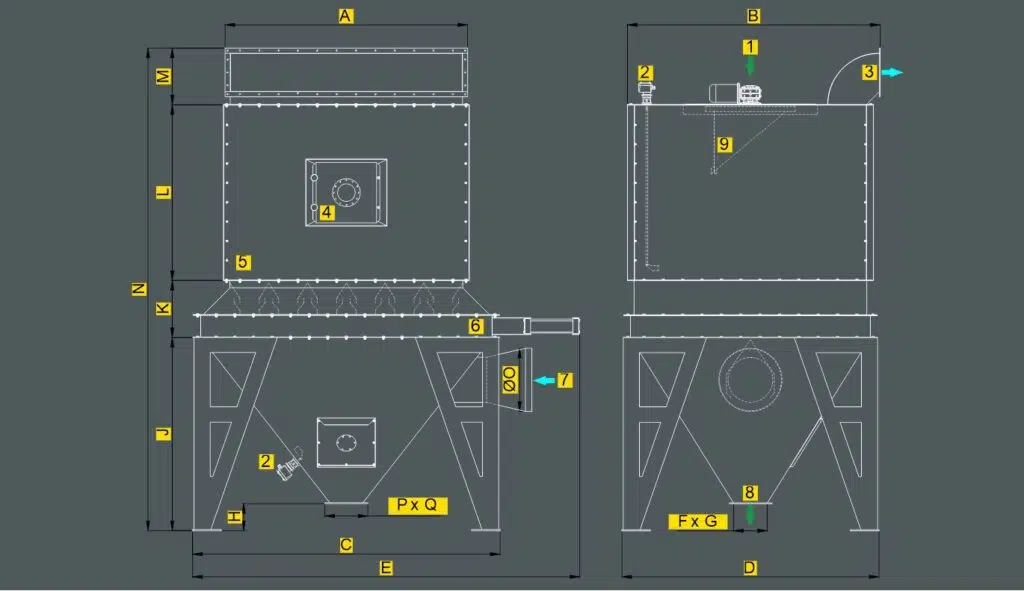

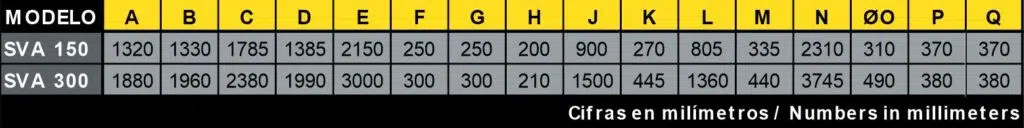

Technical information

1 – Product entry

2 – Level control

3 – Suction duct

4 – Manhole

5 – Temperature exchange chamber

6 – Pneumatic discharge pulsating valve

7 – Air inlet

7 – Air inlet

8 – Download

9 – Rotating distributor (x)

(x) Only on SVA 300

More information in the following links