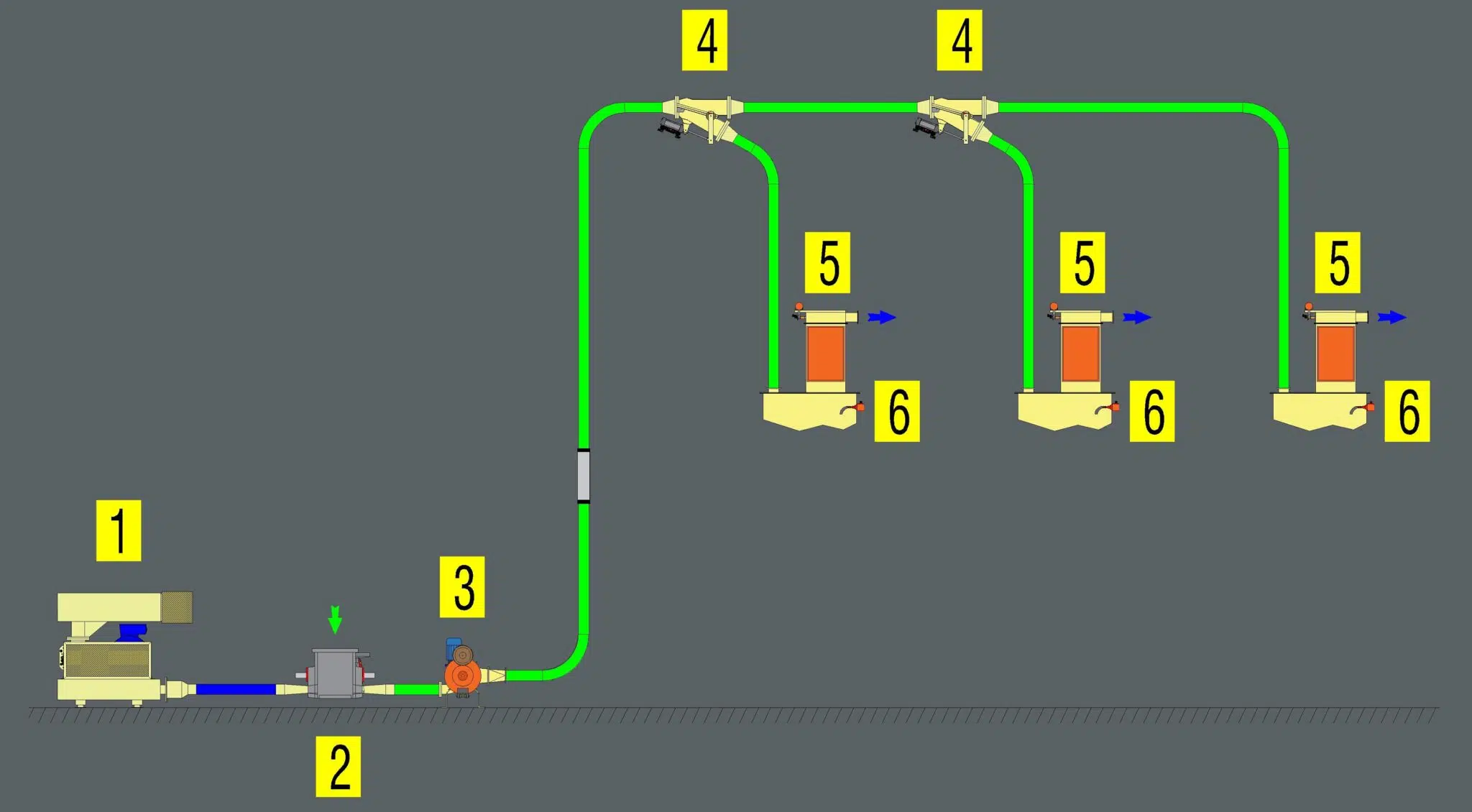

In many pneumatic conveying systems, it is necessary to transport the product to multiple destinations. For this, our diverter valves are used.

Types of pneumatic conveying valves

Primarily, pneumatic conveying valves can be divided as follows:

- VTN Pneumatic Conveying Diverter Valve with Flap: Designed for medium pressures. It is necessary to momentarily interrupt transport to make the diversión.

- VTNGa Rotary Diverter Valve for Pneumatic Conveying: Suitable for high pressures. It does not require interrupting pneumatic transport to make the diversion.

- Square Section Diverter Valve for Pneumatic Conveying VTNQ: Specifically designed for cases where a construction of special wear-resistant steels is required due to the product circulating inside.

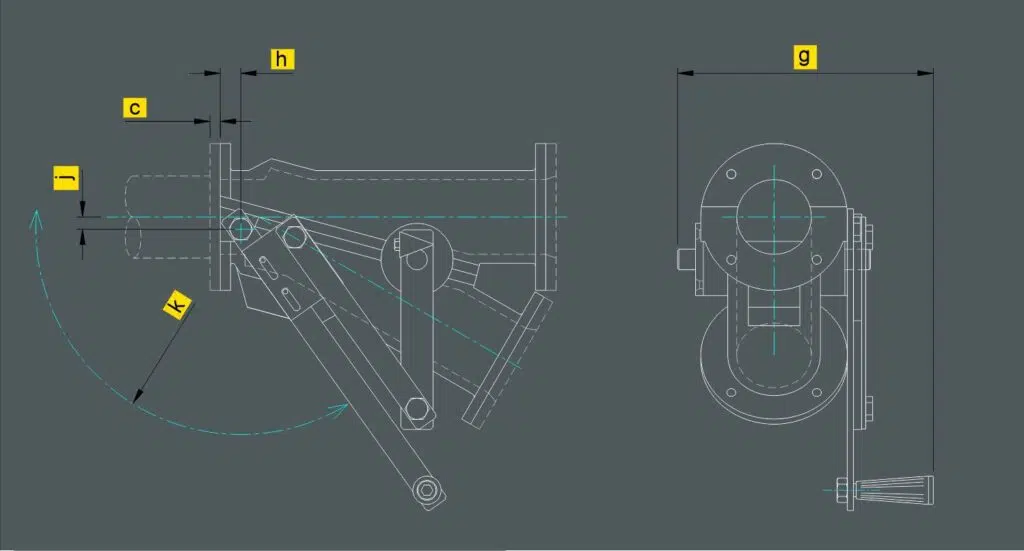

1- VTN Pneumatic Conveying Diverter Valve with Flap:

The VTN diverter valve is used to change the pneumatic conveying route without the need to empty the pipeline beforehand. With its innovative circular section design, our tongue valves ensure a precise, durable seal, minimizing energy loss.

The two-part body construction allows Prillwitz to guarantee that the seat of the movable flap is perfectly machined, ensuring precise sealing and hidden joints that prevent wear, dust/product leakage, and reduce maintenance needs. VTN diverters can be manufactured with manual control or with a pneumatic cylinder and solenoid valve. In the latter case, remote control is possible, facilitating automation. Typically, they are constructed with an aluminum cast body and the rest in carbon steel, though other materials suitable for corrosive products are also available.

Technical information

With pneumatic cylinder and solenoid valve

Manual control

More information in the following links

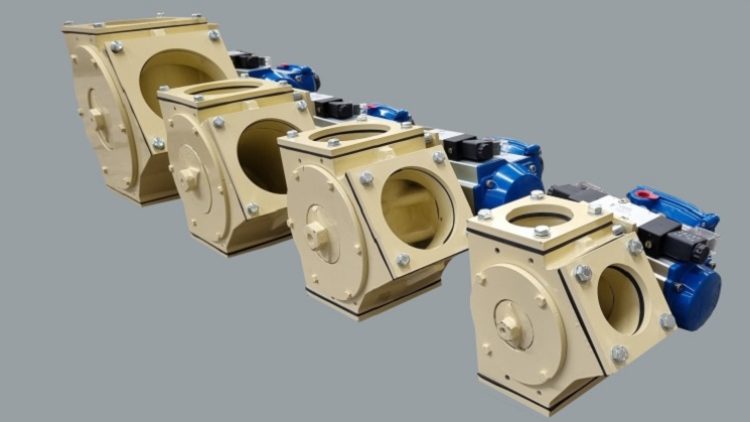

2- VTNGa rotary diverter valve for pneumatic conveying

The VTNGa diverter valve design enables the diversion of products by rotating a rotor that connects one route to another, ensuring a perfect, long-lasting seal, even under high pressures. With a robust design, our VTNGa rotary valves stand out among others for their durability, as they do not have mechanical parts that wear out easily.

VTNGa rotary valves are available with manual control or with a rotary actuator and solenoid valve. Position-detecting microswitches can also be incorporated if needed. They are usually made with an aluminum cast body and rotor, with steel shafts and bronze bushings. Depending on the type of product to be transported, they can be made from various materials.

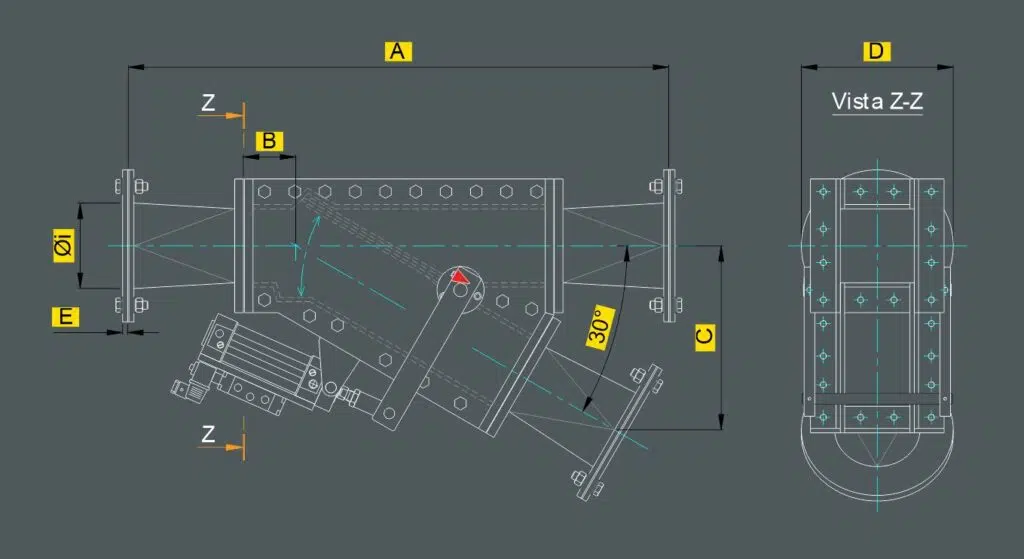

3- Square Section Diverter Valve for Pneumatic Conveying VTNQ

This valve is used to change the conveying path in pneumatic transport systems for bulk materials. It is specifically designed to provide high wear resistance when needed.

The VTNQ valve is composed of several parts bolted together. The path change is achieved by rotating a flap inside the square-section body, ensuring a durable seal.

It can be constructed from various types of steel, although it is particularly designed to be made of wear-resistant steel, making it suitable for use with abrasive materials.

The valve is available with both manual control and pneumatic actuator with solenoid valve. Optionally, it can be supplied with microswitches for position detection.

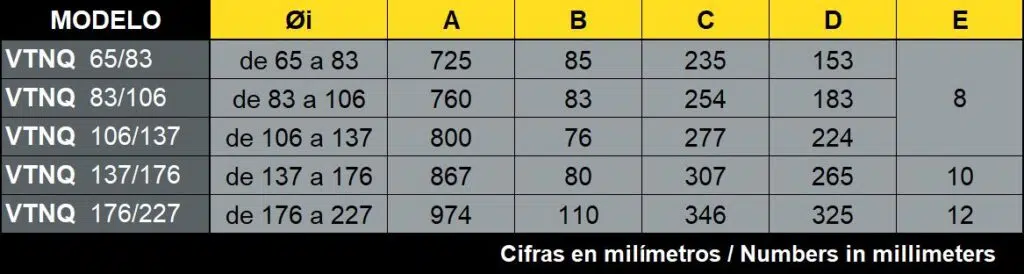

Technical information:

More information in the following links